What is the size of stainless steel manhole cover?

As an important part of modern urban infrastructure, the size of stainless steel manhole cover has attracted widespread attention. The size of stainless steel manhole cover is directly related to its safety, functionality and the coordination of urban landscape. This article will explore in depth the standard size of stainless steel manhole cover, its design principles and its importance in practical applications.

Standard size and classification

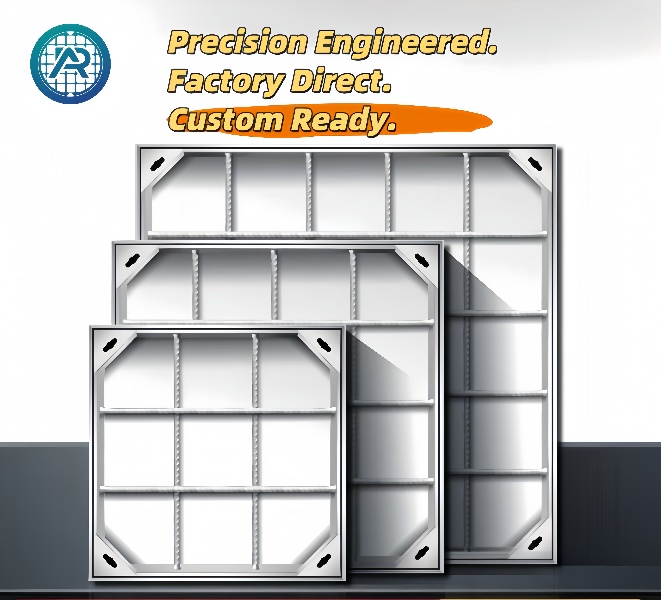

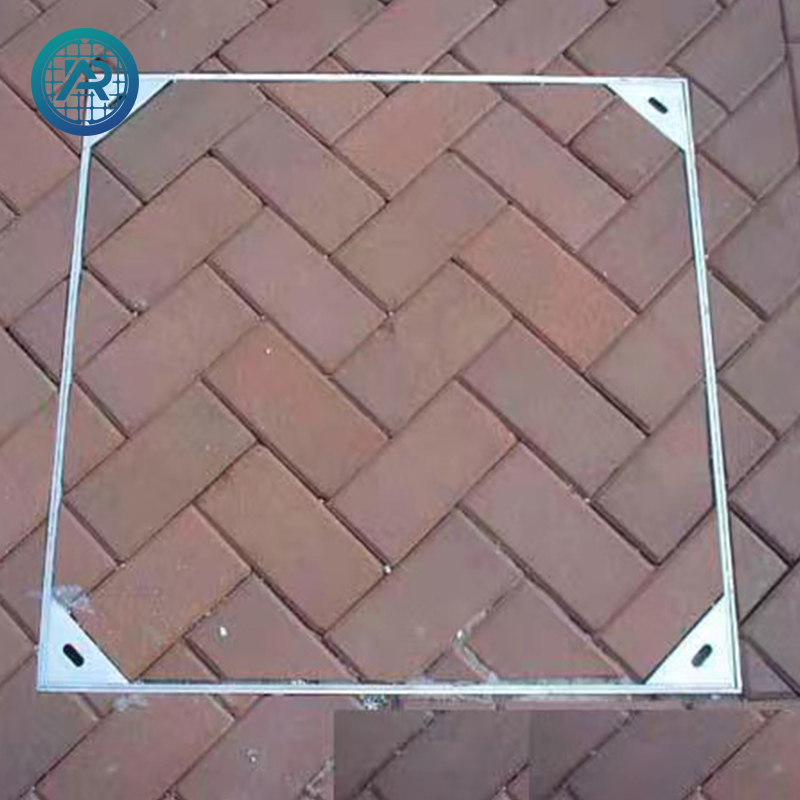

The size of stainless steel manhole cover is usually divided into multiple specifications, mainly according to its application scenario and load-bearing capacity. Common stainless steel manhole cover sizes include round and square. The diameter of round manhole cover is generally 600mm to 900mm, while the side length of square manhole cover is between 500mm and 800mm. In addition, according to the different load-bearing capacity, stainless steel manhole cover can also be divided into three categories: light, medium and heavy, suitable for different traffic environments and usage requirements.

Light stainless steel manhole cover is usually used for sidewalks and green spaces. Its size is relatively small and its load-bearing capacity is less than 5 tons. Medium-sized stainless steel manhole covers are mostly used on ordinary roads, with moderate sizes and a load capacity generally between 5 tons and 25 tons. Heavy-duty stainless steel manhole covers are mainly used on busy roads and industrial sites, with larger sizes and a load capacity of more than 25 tons.

Design principles and specifications

The design of stainless steel manhole covers must follow certain principles and specifications to ensure the effective function and safety of their use. First, the size design of manhole covers must comply with national or industry standards, such as the "Design Specifications for Urban Road Traffic Facilities" and the "Design Specifications for Water Supply and Drainage Pipeline Engineering", which clearly stipulate the size, shape, material and load capacity of manhole covers.

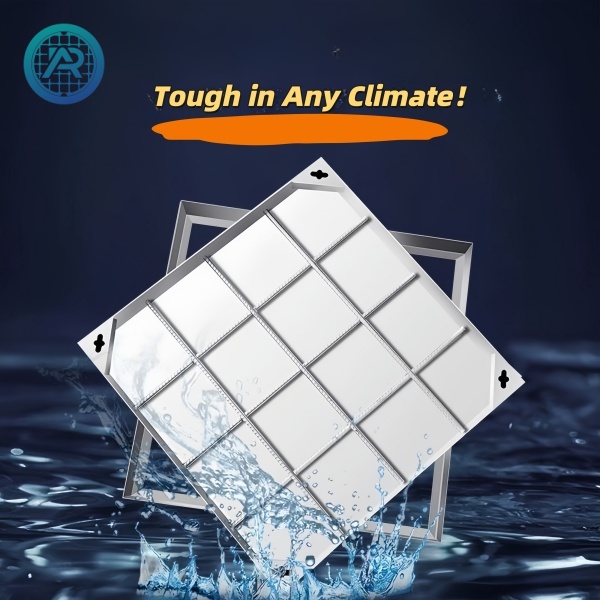

Second, the design of manhole covers should take into account environmental factors in actual applications, such as the road grade, traffic flow, and climatic conditions where the manhole covers are located. For heavy-duty stainless steel manhole covers, their design should pay special attention to compressive strength and durability to cope with frequent heavy-loaded vehicle traffic. For stainless steel manhole covers in landscape areas, their design should take into account both aesthetics and practicality, and the size and shape should be in harmony with the surrounding environment.

Importance in practical applications

The size of the stainless steel manhole cover has an important impact on its practical application. A manhole cover with the right size can not only effectively protect underground facilities, but also avoid safety hazards for vehicles and pedestrians. For example, on the main roads in the city, if the manhole cover is too small, it may not be able to bear the weight of a large vehicle, resulting in damage to the manhole cover or even a traffic accident. Similarly, a manhole cover that is too large may become loose due to insecure installation, causing safety hazards.

In addition, the size of the stainless steel manhole cover is also related to the convenience of maintenance and management. The standardized size design facilitates the unified procurement, installation and replacement of manhole covers, reducing the difficulty and cost of urban management. At the same time, the appropriate size of the manhole cover can also improve the overall coordination of the urban landscape and enhance the beauty and functionality of the city.

In summary, the size design of the stainless steel manhole cover not only involves technical specifications and standards, but also needs to consider a variety of factors in practical applications. Reasonable size selection can ensure the functionality and safety of the manhole cover and provide guarantee for the stable operation of urban infrastructure.

What are the manufacturing processes of stainless manhole cover?

After understanding the size and importance of stainless manhole cover, we further explore the manufacturing process of stainless manhole cover. The manufacturing process of stainless manhole cover is directly related to its quality, durability and service life. Different manufacturing processes will affect the performance and cost of manhole cover, so understanding its manufacturing process is essential for purchasing and using stainless manhole cover.

Material selection and preparation

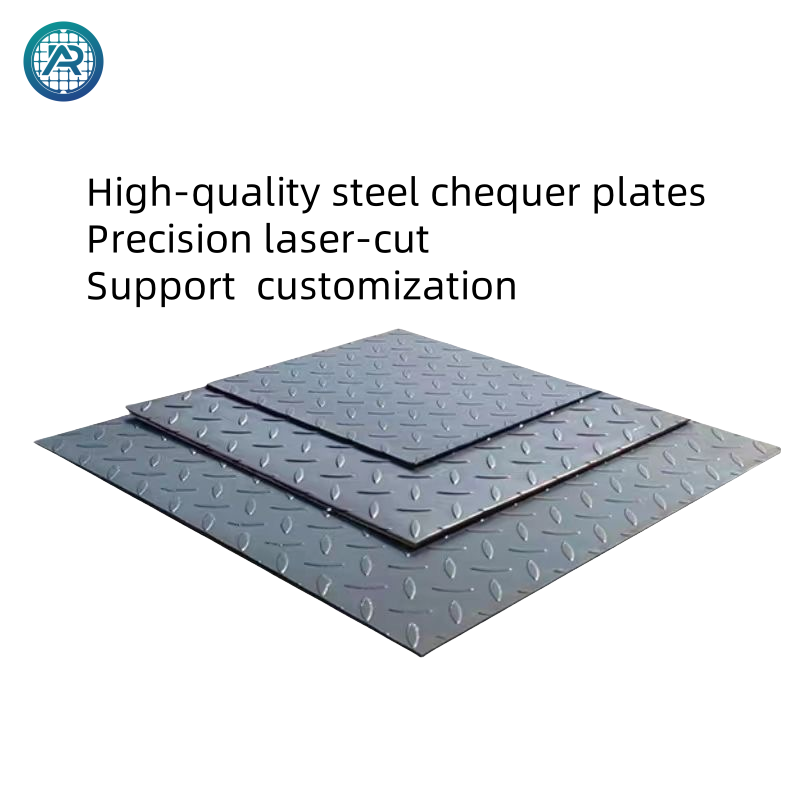

The manufacturing of stainless manhole cover first requires the selection of suitable stainless steel materials. Commonly used stainless steel materials include 304 stainless steel and 316 stainless steel. 304 stainless steel has excellent corrosion resistance and good processing performance, which is suitable for manhole cover manufacturing in general environment; while 316 stainless steel is often used in coastal areas and chemical sites due to its higher corrosion resistance.

After material selection, a series of preparations need to be made for stainless steel, including shearing, bending, welding and other processes. The purpose of these processes is to process stainless steel sheets into the shape and size required for manhole cover, laying the foundation for subsequent manufacturing processes.

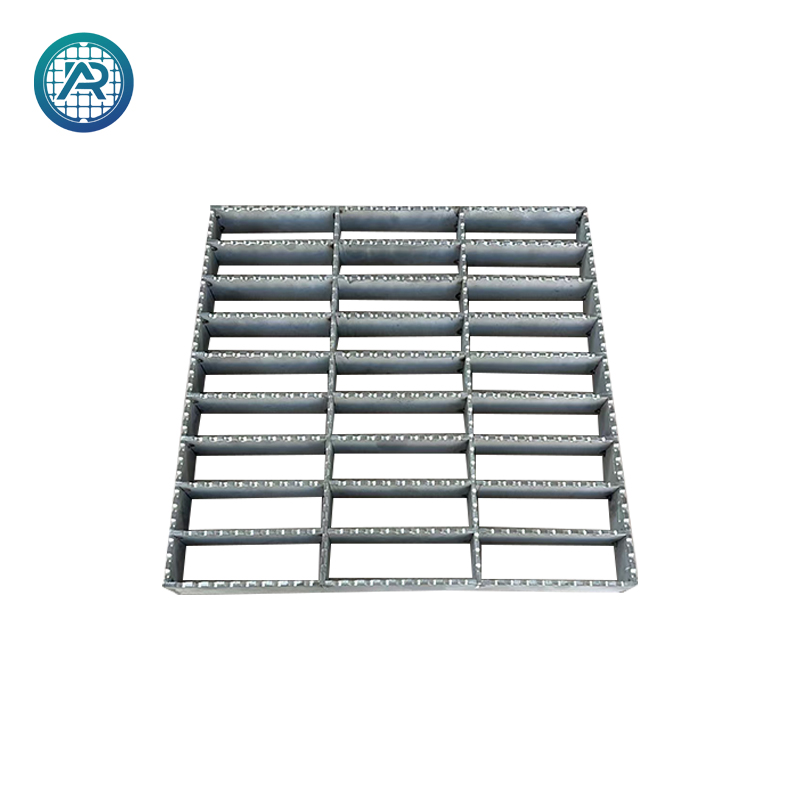

Stamping and forming

Stamping is one of the main processes for manufacturing stainless manhole cover. The stamping process uses a punch and a die to process stainless steel sheets into the basic shape of a manhole cover. This process includes steps such as cutting, punching, and folding. The stamping process is characterized by high efficiency and high precision, and can mass-produce manhole cover products with uniform size and stable quality.

In the stamping process, the design and manufacture of the mold are crucial. The precision and quality of the mold directly affect the dimensional accuracy and surface quality of the manhole cover. Therefore, the design of the mold must fully consider the size requirements and use environment of the manhole cover to ensure that the size of the manhole cover after forming meets the design specifications and has a good surface finish.

Welding and assembly

The welding process also occupies an important position in the manufacture of stainless manhole cover. Welding is mainly used for the assembly and reinforcement of manhole covers to make the manhole covers have higher strength and durability. Commonly used welding methods include argon arc welding, spot welding, and laser welding. Argon arc welding is widely used in the manufacture of stainless manhole covers because of its high welding quality and beautiful welds.

During the welding process, it is necessary to pay attention to controlling the welding temperature and speed to prevent the stainless steel material from being deformed or damaged due to overheating. At the same time, the welded manhole cover needs to undergo strict quality inspection to ensure that the weld is firm, without cracks or pores, so as to ensure the service life and safety of the manhole cover.

Surface treatment and inspection

The surface treatment process of the stainless manhole cover includes pickling, polishing and spraying. Pickling can remove the oxide scale and impurities on the surface of stainless steel and enhance its corrosion resistance; polishing makes the surface of the manhole cover smoother and more beautiful, improving its overall quality; spraying can add a protective layer to the manhole cover as needed to further improve its anti-corrosion performance.

After completing the surface treatment, the stainless manhole cover needs to undergo strict quality inspection. The inspection content includes dimensional accuracy, surface quality, welding quality and other aspects. Through inspection, it can be ensured that the manhole cover meets the design standards and use requirements before leaving the factory, and ensures its reliability and safety in practical applications.

In summary, the manufacturing process of the stainless manhole cover involves multiple links such as material selection, stamping, welding assembly and surface treatment. Each process step is directly related to the final quality and performance of the manhole cover. Understanding these manufacturing processes will help us make more wise choices when purchasing and using stainless manhole covers.

What are the methods for the maintenance and care of stainless manhole covers?

After a deep understanding of the size and manufacturing process of stainless manhole covers, we need to discuss the maintenance and care of stainless manhole covers. The maintenance and care of stainless manhole covers directly affects their service life and functional performance. Scientific maintenance methods can not only extend the service life of manhole covers, but also ensure their safety and reliability during use.

Regular inspection and cleaning

Regular inspection is one of the important methods for maintaining SS manhole covers. The inspection content includes the surface condition of the manhole cover, the firmness of the welding parts, the matching of the manhole cover and the manhole seat, etc. Through regular inspections, potential problems with the manhole cover can be discovered in time to avoid safety accidents caused by damage to the manhole cover.

In addition to regular inspections, the cleaning of the manhole cover is also very important. The frequency and method of cleaning should be determined according to the environment in which the manhole cover is located. In a heavily polluted environment, such as an industrial area or a chemical plant, the surface of the manhole cover is prone to oil, dust and chemicals, and frequent cleaning is required to prevent these impurities from corroding the stainless steel material. When cleaning, you can use a neutral detergent and a soft cloth to wipe it, and avoid using detergents containing chloride ions to avoid corrosion to the stainless steel surface.

Anti-corrosion treatment and repair

Although stainless steel materials have strong corrosion resistance, ss manhole covers may still be corroded in some special environments, such as coastal cities or chemical plants. Therefore, for these special environments, the manhole cover needs to be treated with anti-corrosion. Common anti-corrosion treatment methods include spraying anti-corrosion coatings, electroplating protective layers, etc. These methods can form a protective film on the surface of the manhole cover, effectively preventing the invasion of corrosive substances, thereby extending the service life of the manhole cover.

When corrosion or damage is found on the surface of the ss manhole cover, it needs to be repaired in time. For minor surface scratches or rust spots, they can be removed by grinding and polishing, and appropriate anti-corrosion treatment can be performed. For more serious corrosion or structural damage, it may be necessary to replace the damaged part or the entire manhole cover. During the repair process, attention should be paid to using stainless steel that matches the raw materials to ensure that the performance of the repaired manhole cover is not affected.

Installation and adjustment

Correct installation is an important prerequisite for ensuring the normal use of the ss manhole cover. The installation of the manhole cover should be carried out strictly in accordance with the design specifications to ensure that the manhole cover fits tightly with the well seat without loosening or tilting. The following points should be noted during the installation process:

Foundation preparation: The foundation of the manhole seat needs to be flat and solid to ensure that the manhole cover does not shake after being placed. Before installation, the debris and dirt on the manhole seat should be removed to ensure that there is no gap between the manhole cover and the manhole seat.

Match adjustment: After installation, the fit between the manhole cover and the manhole seat should be checked to ensure that the manhole cover can be opened and closed freely. If necessary, the height and position of the manhole cover can be adjusted by adjusting the gasket or cushion layer to make it flush with the road surface.

Fix measures: In some occasions where anti-theft or anti-theft cover displacement is required, fixing measures can be taken, such as setting a locking device or anti-theft bolt between the manhole cover and the manhole seat to ensure that the manhole cover is safe and stable.

Precautions for daily use

In daily use, the ss manhole cover should be protected from excessive impact and heavy load. Although the ss manhole cover has a high load-bearing capacity, long-term overload use or heavy object impact may cause the manhole cover to deform or be damaged. Therefore, when driving or parking heavy vehicles on the manhole cover, special attention should be paid to its load-bearing capacity to avoid the manhole cover from being subjected to pressure exceeding the designed load-bearing capacity.

In addition, during the use of manhole covers, long-term exposure to corrosive chemicals such as strong acids and alkalis should be avoided. These substances will accelerate the corrosion of stainless steel materials and reduce their service life. If it is inevitable to come into contact with these chemicals, it should be cleaned and anti-corrosion treated in time to ensure that the surface of the manhole cover is clean and pollution-free.

In summary, the maintenance and care of ss manhole covers include regular inspection and cleaning, anti-corrosion treatment and repair, correct installation and adjustment, and daily use precautions. Through scientific maintenance methods, the service life of ss manhole covers can be effectively extended to ensure its safety and reliability in practical applications.

Conclusion

Through the above in-depth discussion on the size, manufacturing process, maintenance and future development trend of stainless steel manhole cover, we can see that as an important part of urban infrastructure, the design, manufacturing and maintenance of stainless steel manhole cover require a high degree of professionalism and scientificity. Reasonable size design, advanced manufacturing process, scientific maintenance methods and forward-looking thinking on future development are all key factors to ensure the safety, reliability and durability of stainless steel manhole cover.

With the advancement of science and technology and the acceleration of urbanization, stainless steel manhole cover will usher in more development opportunities and challenges. New materials, new technologies and intelligent applications will continue to promote the performance improvement and function expansion of stainless steel manhole cover. At the same time, the deepening of environmental protection and sustainable development concepts will lead stainless steel manhole cover to a greener and more environmentally friendly direction.

In the future urban construction and management, stainless steel manhole cover will play an increasingly important role. Through continuous innovation and optimization, stainless steel manhole cover will provide solid guarantee for the stable operation of urban infrastructure and the intelligentization of urban management, and contribute to the safety, convenience and sustainable development of modern cities.