Is the manhole cover ductile iron?

Material and type of manhole cover

The most common metal manhole cover you see is cast iron, but this cast iron manhole cover is not a single material product. Cast iron manhole covers can be divided into gray cast iron manhole covers and ductile iron manhole covers according to the manufacturing process and added elements.

Gray cast iron manhole cover is the most common type of cast iron manhole cover. It is made by pouring iron into a mold together with some carbon and silicon, giving the cover the usual strength and durability. The advantage of gray cast iron is that it is low in cost and simple in manufacturing process, so it is widely used in urban roads, residential areas and other places. However, gray cast iron is more brittle and prone to cracks or fractures under heavy pressure.

In contrast, ductile iron manhole cover is made by adding magnesium to cast iron, so that the cast iron forms a spheroidal graphite structure during the cooling process. This spheroidal graphite structure greatly enhances the toughness and strength of cast iron, making the ductile iron manhole cover more durable and less prone to fracture than the gray cast iron manhole cover. Therefore, ductile iron manhole cover is more suitable for roads and public places with heavy traffic and high bearing pressure.

Why choose ductile iron manhole cover?

The main reason for choosing ductile iron manhole cover is its superior mechanical properties and safety. First, ductile iron has high tensile strength and ductility, and can withstand greater pressure and impact, thereby improving the service life and safety of the manhole cover. Secondly, ductile iron manhole cover is not easy to deform or break under high load, reducing safety hazards and traffic accidents caused by manhole cover damage.

In addition, the corrosion resistance of ductile iron manhole is also better than that of gray cast iron, and it is suitable for various harsh environmental conditions. In urban construction, the anti-theft problem of manhole covers has also received more and more attention. Due to its high value and heavy weight, ductile iron manhole is not easy to be stolen, which further ensures the safety of public facilities.

Application field of ductile iron manhole

Ductile iron manhole is widely used in municipal engineering, road traffic, communication and power and other fields. In municipal engineering, ductile iron manhole is usually used for the entrances and exits of urban drainage and water supply pipelines. Its high strength and corrosion resistance ensure the normal operation of underground facilities. In terms of road traffic, ductile iron manholes are widely installed in urban main roads, highways and other busy traffic areas, effectively preventing the manhole covers from being damaged and displaced under heavy pressure, ensuring the safety and smoothness of roads.

In the field of communications and power, ductile iron manholes are mainly used to protect important facilities such as underground cables and optical fiber communication lines. Its superior mechanical properties and anti-theft design not only ensure the safe operation of communications and power facilities, but also reduce the cost of maintenance and replacement.

What should be paid attention to when installing and maintaining ductile iron cover?

Steps to install ductile iron cover

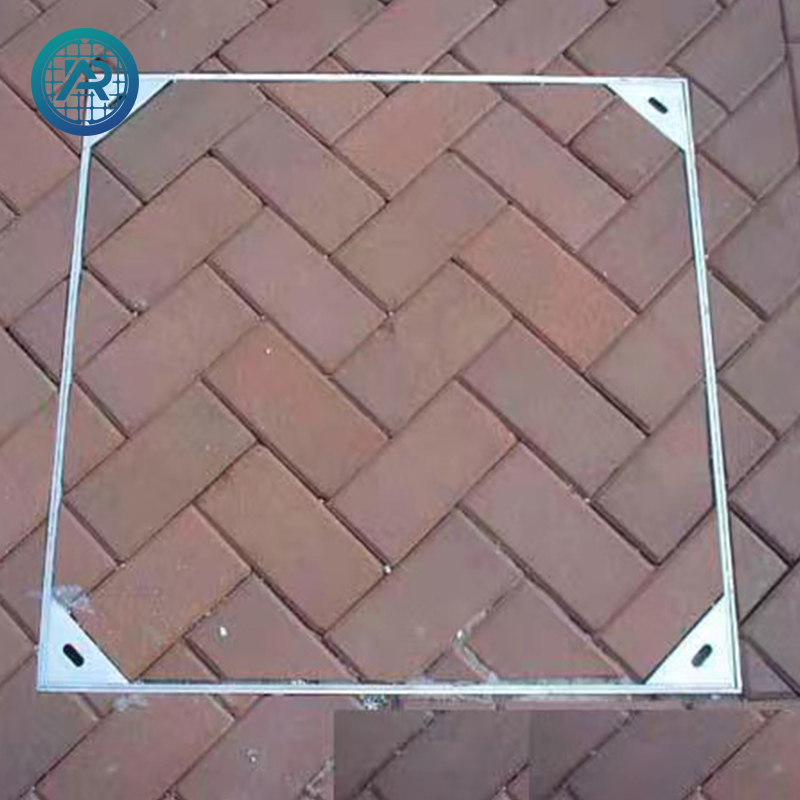

When installing ductile iron cover, you first need to clean and prepare the installation location. Make sure the ground around the wellhead is flat and solid, and remove all debris and dust. Next, choose a suitable manhole cover according to the size and shape of the wellhead, and usually reserve a certain gap to facilitate the installation and removal of the manhole cover.

During the installation process, the manhole cover needs to be placed on the wellhead steadily, and a special tool is used to fix the manhole cover and the well seat firmly. Make sure there is no gap and looseness between the manhole cover and the well seat to prevent vibration and noise when the vehicle passes by. In addition, it is necessary to regularly check and maintain the fixing bolts of the manhole cover to ensure that it is firm and reliable.

Key points for maintaining ductile iron cover

The maintenance of ductile iron cover mainly includes regular inspection, cleaning and anti-corrosion treatment. Regularly check the surface and periphery of the manhole cover to ensure that there are no cracks, deformation or looseness. If the manhole cover is found to be damaged or loose, it should be replaced or repaired in time to avoid safety hazards.

Clean the debris and dirt on the surface of the manhole cover to keep the manhole cover clean and beautiful. At the same time, regularly clean the shaft under the manhole cover to prevent debris from blocking drainage and ventilation. For the anti-corrosion treatment of the manhole cover, anti-corrosion paint can be applied regularly to increase its corrosion resistance and service life.

How to deal with the problem of manhole cover damage and loss?

In actual use, the damage and loss of manhole covers are inevitable. For damaged manhole covers, new manhole covers should be replaced in time, and the installation position and fixing of the manhole covers should be checked to ensure their safety and reliability. For lost manhole covers, they should be reported to the relevant departments as soon as possible, and temporary protective measures should be taken, such as setting up warning signs or temporary coverings to prevent accidents to pedestrians and vehicles.

At the same time, strengthen the management and monitoring of manhole covers, install monitoring equipment or strengthen inspections to prevent theft or malicious destruction of manhole covers. In municipal construction, it is possible to consider adopting a more anti-theft and anti-damage manhole cover design, such as increasing the weight of the manhole cover, setting up anti-theft locks and other measures to improve the safety and anti-theft performance of the manhole cover.

Why is ductile iron manhole cover more popular than manhole covers made of other materials?

Advantages of ductile iron manhole cover

Compared with manhole covers made of other materials, ductile iron manhole has obvious advantages. First, ductile iron manhole has higher strength and toughness, can withstand greater pressure and impact, and is not prone to breakage and deformation. Secondly, ductile iron manhole has better corrosion resistance than ordinary cast iron manhole covers, is suitable for various harsh environmental conditions, and has a longer service life.

In addition, ductile iron manhole has better anti-theft performance. Due to its high value and heavy weight, it is more difficult to steal, which effectively reduces the risk of manhole cover theft. The appearance design of ductile iron cover is also more beautiful, and it can be customized according to different application scenarios to meet the different needs of municipal construction.

Limitations of manhole covers made of other materials

In contrast, manhole covers made of other materials have some limitations in use. Although plastic manhole covers have lower costs, they have poor strength and durability, and are easily deformed or damaged under heavy pressure, affecting safety and service life. Concrete manhole covers are relatively bulky, inconvenient to install and maintain, and are susceptible to corrosion and wear.

Although steel manhole covers have high strength, they have poor corrosion resistance, are prone to rust and corrosion, and have a short service life. Although composite manhole covers have certain strength and corrosion resistance, they are expensive, and have certain brittleness in actual use, and are prone to fracture and breakage.

Promotion and application of ductile iron cover in municipal construction

In municipal construction, ductile iron cover has gradually become the mainstream choice due to its superior performance and wide application. When choosing manhole covers, municipal departments are increasingly inclined to use ductile iron cover to improve the safety and reliability of urban infrastructure. At the same time, the wide application of ductile iron manhole cover has also promoted the progress of related technologies and the development of the industry.

In order to further promote the application of ductile iron manhole cover, municipal departments should also strengthen the management and maintenance of manhole covers, establish a complete manhole cover archive and monitoring system, and ensure the safe use of manhole covers. In addition, we should actively carry out anti-theft and anti-loss publicity for manhole covers, improve the public's safety awareness, and jointly maintain the city's public facilities.

Summary

Ductile iron manhole cover has become an indispensable and important part of municipal construction with its superior performance and wide application. Through the understanding and research of ductile iron manhole cover, we can not only better understand its important role in urban infrastructure, but also provide more reference and reference for municipal construction and maintenance. It is hoped that in the future municipal construction, ductile iron manhole cover can continue to play its advantages and provide safer and more reliable protection for urban development and residents' lives.