What are galvanized grates?

Galvanized grates is a metal structural material formed through special processing and is widely used in construction, industry, transportation and other fields. Its production process mainly includes two stages: production of steel grating and hot-dip galvanizing. Below we describe these two stages in detail and their advantages in different applications.

Production process

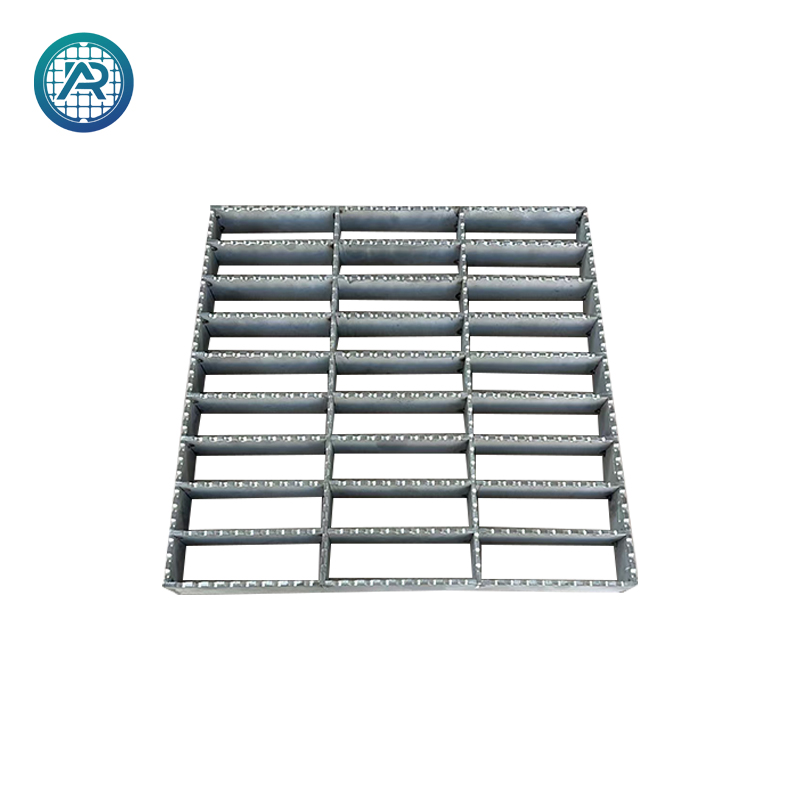

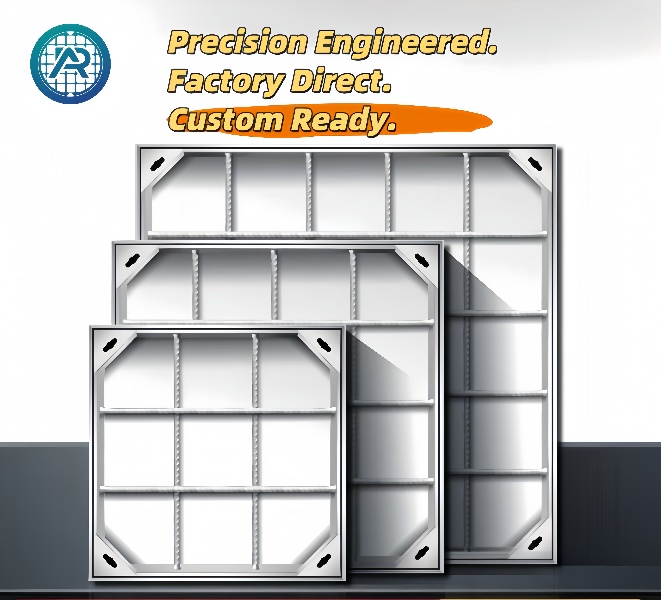

First of all, steel grating plates are made of high-strength steel through cold bending or hot rolling. The design of steel grating panels usually has a uniform pore structure, which can not only bear a large weight but also ensure good ventilation and drainage effects. Steel grating panels can be welded or locked together to form a strong grid structure, which makes them excellent when carrying heavy loads.

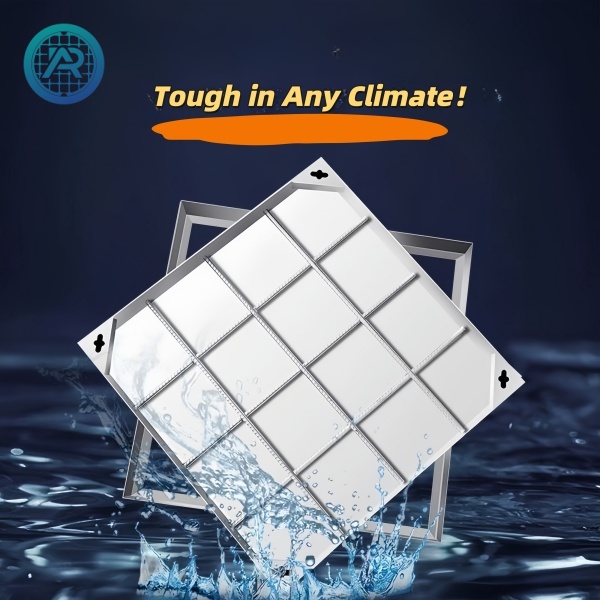

Next is hot dip galvanizing. Hot-dip galvanizing refers to immersing steel in molten zinc to form a zinc-iron alloy layer on its surface. This process not only increases the corrosion resistance of the steel grating, but also significantly extends its service life. The thickness and uniformity of the zinc layer are key factors in ensuring the quality of galvanized grates. Premium hot-dip galvanizing provides long-term protection in harsh environments, allowing galvanized grates to maintain their structural integrity in a variety of applications.

Application areas

galvanized grates have wide applications in many fields. The following are some typical application scenarios:

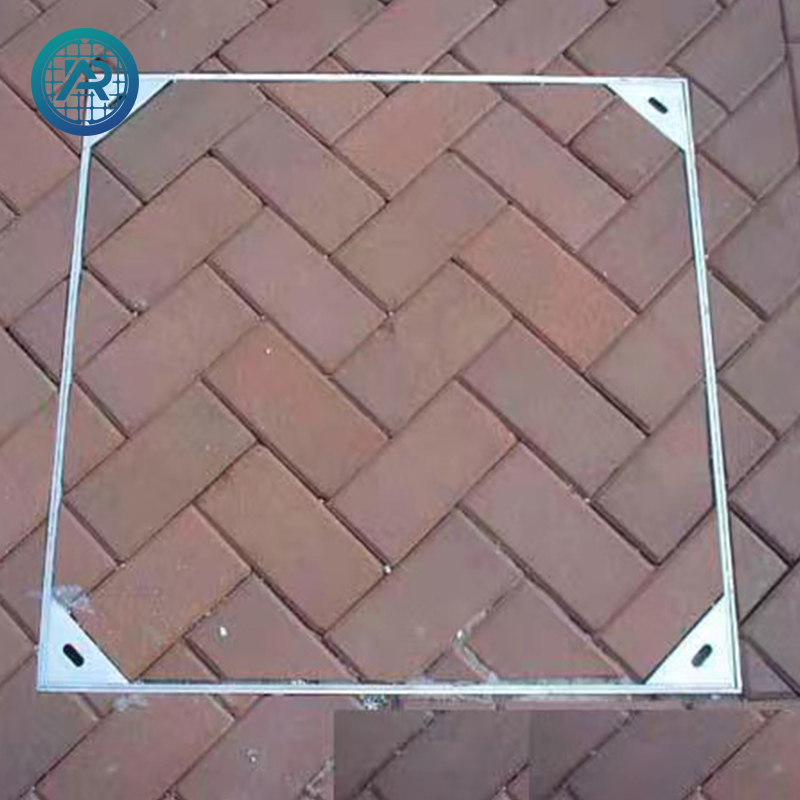

Construction Engineering: In construction engineering, galvanized grates are often used to make stair treads, walkways, and platforms. Its excellent anti-slip properties and durability make it ideal for these locations.

Industrial field: In the industrial field, galvanized grates are often used in floors and drainage systems in chemical plants, power plants, sewage treatment plants and other places. Its good ventilation and drainage properties can effectively prevent the accumulation of water and dirt, thereby ensuring the safety and hygiene of the factory.

Transportation facilities: galvanized grates are also widely used in transportation facilities, such as bridges, tunnels, airports, etc. Its rugged nature can withstand heavy traffic pressure, while its anti-slip surface treatment improves the safety of pedestrians and vehicles.

Why does galvanized bar grating have such a wide range of applications?

After understanding the production process and application fields of galvanized bar grating, we can't help but ask: Why does galvanized bar grating have such a wide range of applications? What are the unique advantages of this material that make it so popular in various industries?

Excellent anti-corrosion properties

First of all, galvanized bar grating has extremely excellent anti-corrosion properties. Steel is susceptible to oxidative corrosion in the natural environment, and a protective zinc layer is formed on the surface of the hot-dip galvanized steel grating. This zinc layer can not only effectively prevent the intrusion of oxygen and moisture, but also continue to protect the steel through the self-repairing effect of the zinc-iron alloy when the zinc layer is damaged. This anti-corrosion performance makes galvanized bar grating perform particularly well outdoors and in harsh environments, reducing the frequency of maintenance and replacement, thereby reducing long-term use costs.

High strength and lightweight construction

Another significant advantage of galvanized bar grating is its high strength and lightweight construction. After being cold-formed or hot-rolled, the steel grating has high strength and can carry heavy objects. Hot-dip galvanizing does not significantly increase its weight, making galvanized bar grating both strong and lightweight. This characteristic is particularly important in the construction and industrial fields because it not only reduces the difficulty of construction, but also improves construction efficiency.

Good ventilation and drainage properties

The pore structure design of galvanized bar grating gives it good ventilation and drainage properties. This feature is very important in many application scenarios. For example, in industrial plants, good ventilation can reduce the accumulation of harmful gases and improve workers' working environment; in outdoor facilities, good drainage performance can prevent water accumulation, thereby reducing slips and other safety hazards. This versatility makes galvanized bar grating work well in a variety of projects.

How to choose the right galvanised grating?

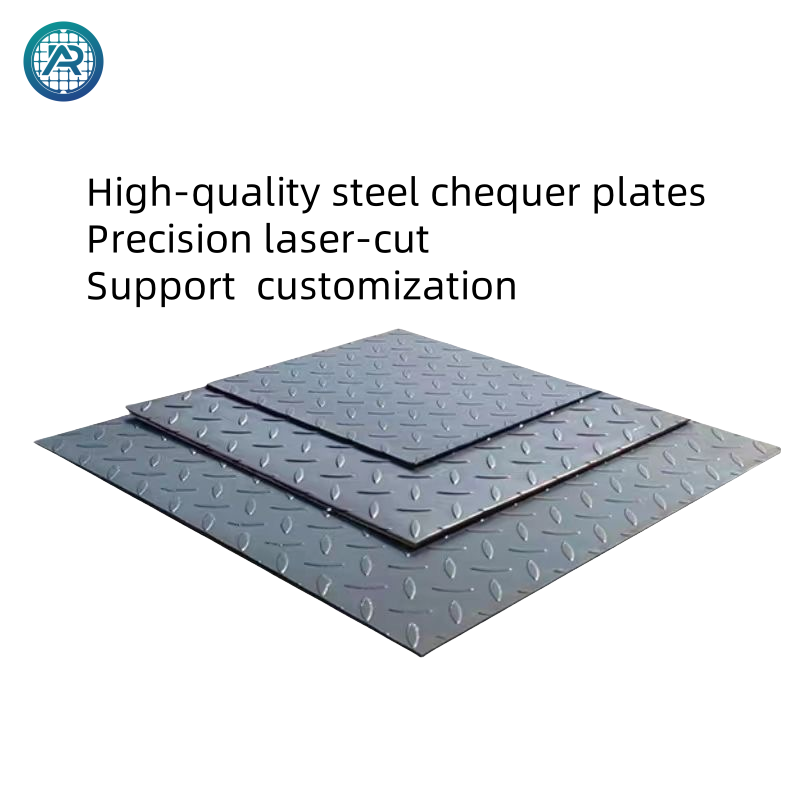

Since galvanised grating has so many advantages, how should we choose the right galvanised grating in practical applications? This requires considering multiple factors, including material quality, size specifications and surface treatment.

Material quality

The first thing to consider is the material quality. High-quality steel and galvanizing process are the basis for ensuring the long-term service life of galvanised grating. When choosing galvanised grating, it should be ensured that the steel used meets the relevant standards and undergoes strict quality inspection. At the same time, the quality of hot-dip galvanizing treatment is also crucial. The thickness and uniformity of the zinc layer directly affect the anti-corrosion performance and service life of the grating.

Size specifications

The second is the choice of size specifications. Galvanised grating has a variety of specifications, and the selection of suitable specifications depends on the specific application requirements. For example, in places where heavy objects are carried, the thickness and mesh size of the grating need to be large enough to ensure its load-bearing capacity; in places where ventilation or drainage is required, a grating with a smaller mesh should be selected to improve its ventilation and drainage performance.

Surface treatment

Finally, surface treatment is also an important factor to consider when choosing galvanised grating. In addition to the standard hot-dip galvanizing treatment, you can also choose gratings with other surface treatments, such as spraying or painting. These additional surface treatments can further enhance the anti-corrosion performance and aesthetics of the grating, and are suitable for some places with high requirements for appearance.

Summary

In summary, galvanised grating, as a high-performance metal structural material, has been widely used in many fields such as construction, industry, and transportation due to its excellent anti-corrosion performance, high strength and lightweight structure, as well as good ventilation and drainage performance. When choosing suitable galvanized grates, we need to comprehensively consider multiple factors such as material quality, size specifications and surface treatment to ensure its best performance in specific applications. Through reasonable selection and use, galvanized grates can play its superior performance in various environments and provide reliable protection for our production and life.