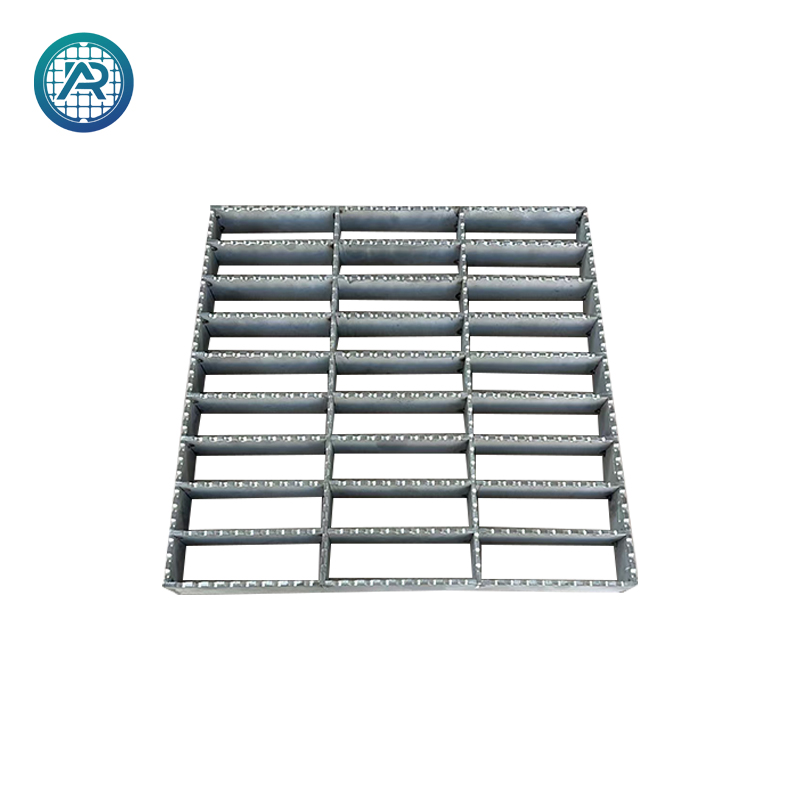

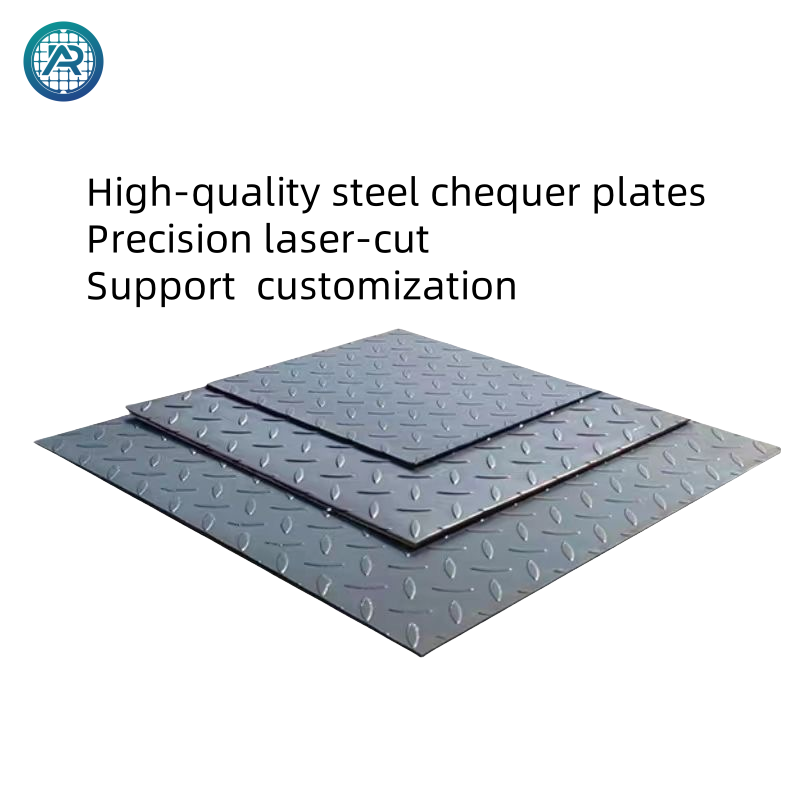

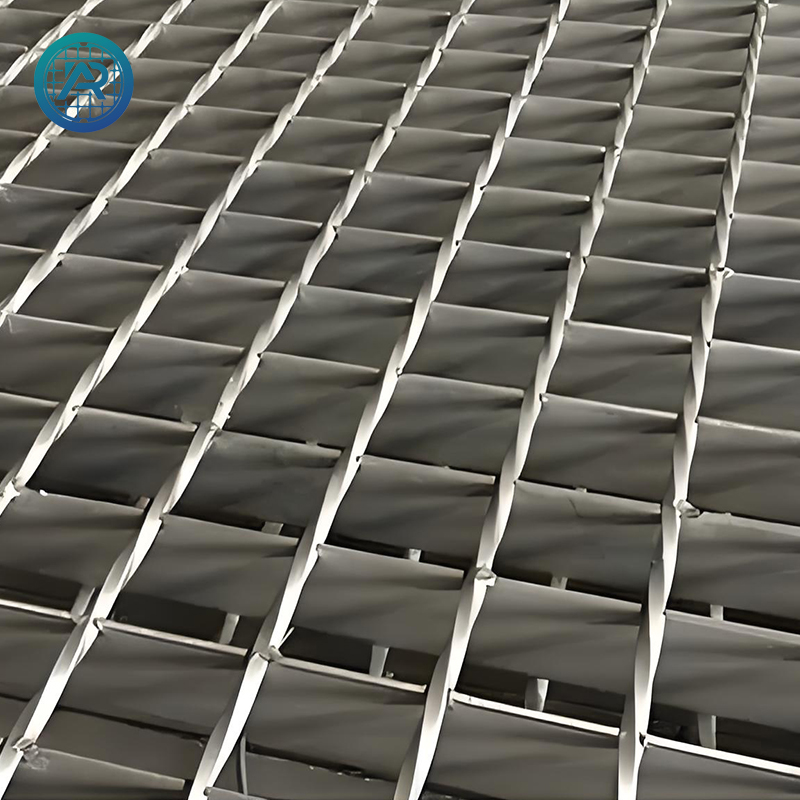

Galvanized grate is a metal grating structure, commonly made of steel or other metals, treated with a galvanization process to enhance its corrosion resistance. Galvanization forms a protective layer on the metal's surface, preventing oxidation and rust, thus significantly extending the grating's lifespan. Galvanized grate is used in various applications such as platforms, walkways, drainage systems, and more, particularly in environments where corrosion resistance is crucial.

Key Features of Galvanized Grate

Excellent Corrosion Resistance

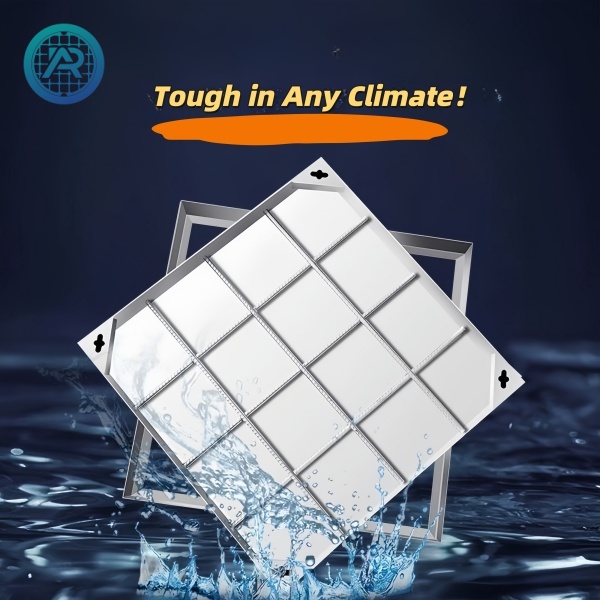

Galvanized grate’s primary advantage lies in its exceptional resistance to corrosion. The galvanization process forms a protective layer on the steel, preventing the formation of rust and significantly increasing durability, especially in environments like cement plants, chemical factories, and marine engineering.

High Strength and Load-Bearing Capacity

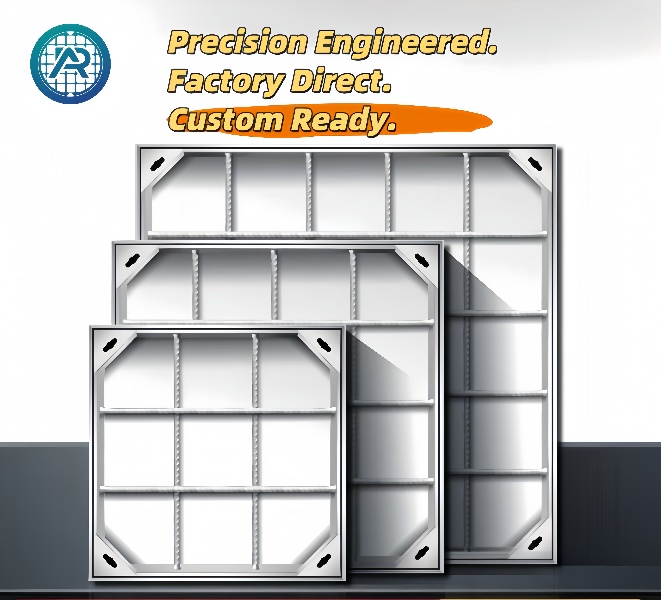

Galvanized grate is designed to withstand high loads and heavy traffic. It’s widely used in industrial buildings, machinery, and transportation facilities, where high strength is necessary.Lightweight and Easy to Install

Compared to other heavy materials, galvanized grate is lightweight, making it easier to transport and install. Its modular design facilitates quick assembly, improving the efficiency of construction projects.Eco-friendly and Sustainable

Galvanized grate is made from recyclable steel, contributing to environmental sustainability. The galvanization process also uses environmentally friendly materials and technologies.

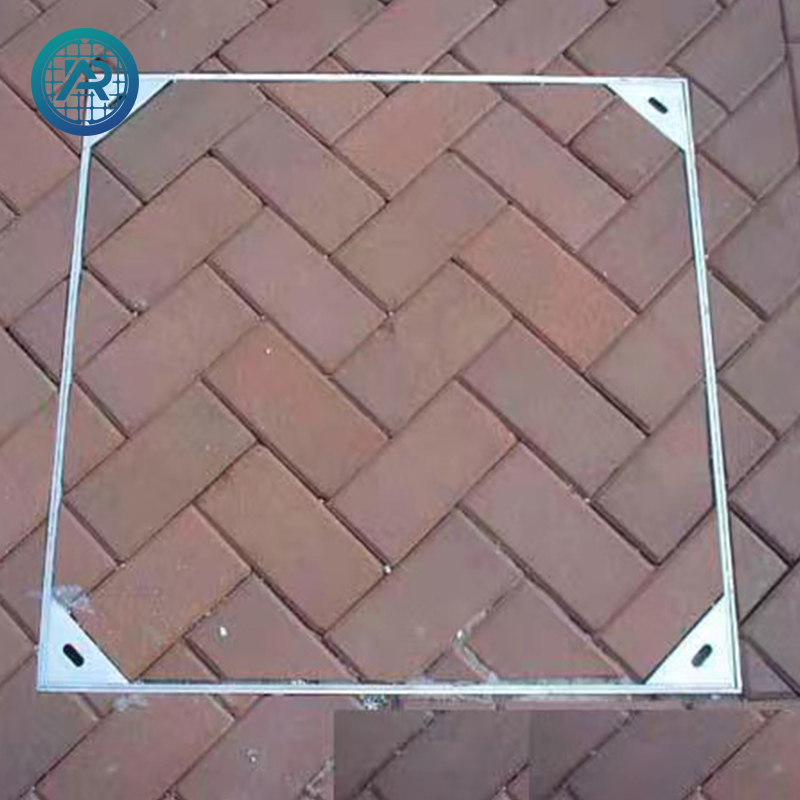

Applications of Galvanized Grating

Due to its excellent properties, galvanized grating is widely used in various sectors. In the construction industry, it is used for platforms, walkways, and fences. In industrial sectors like mining, electricity, and chemicals, galvanized grating is commonly applied in production lines, ventilation, and drainage systems. It is also used in public infrastructure for projects like roads and bridges.

Advantages of Galvanized Grating

Superior Corrosion Resistance

High Load-Bearing Capacity

Space-saving Design

Eco-friendly

Disadvantages of Galvanized Grating

High Cost

Limited Wear Resistance

Aesthetic Limitations

Conclusion

Galvanized grating is an essential component in many industries due to its outstanding corrosion resistance, high strength, and light weight. However, its high cost and limited wear resistance may make it less cost-effective in some situations. Nonetheless, its application potential remains vast, especially in corrosive and heavy-duty environments.