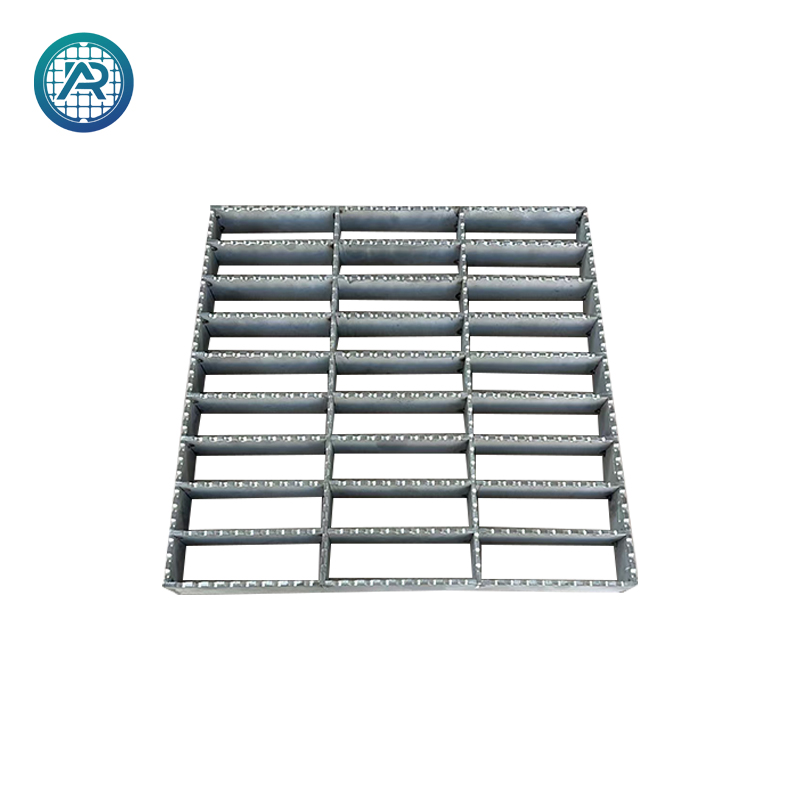

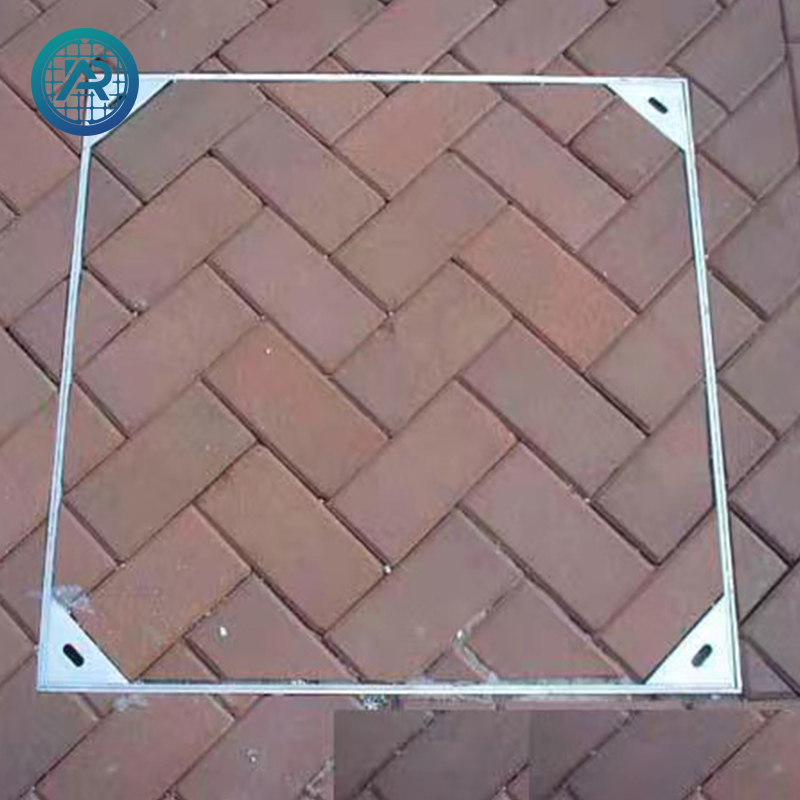

1. galvanized grate: The Cost-Effective Option

galvanized grate, as the name suggests, is made by applying a layer of zinc onto steel to enhance its corrosion resistance. It is typically produced from low-carbon steel, and the zinc coating is applied through either hot-dip or cold-dip galvanizing methods.

One of the most significant advantages of galvanized grate is its cost-effectiveness. Compared to stainless steel grate, galvanized grate is made from lower-cost materials, and its production process is less complicated, resulting in a lower market price. For projects with a limited budget or those that do not require exceptionally high grating strength, galvanized grate offers the best value for money.

1.2 Corrosion Resistance

galvanized grate is more resistant to corrosion compared to regular steel, thanks to the protective zinc layer. In environments with moderate humidity or exposure to water, galvanized grate can effectively prevent rust and corrosion. However, in extreme conditions, such as marine environments or areas with high levels of chemical exposure, the zinc layer may degrade over time, reducing the grating's effectiveness.

1.3 Maintenance Simplicity

galvanized grate is relatively easy to maintain. A periodic inspection of the zinc coating and necessary repairs can extend the grating's lifespan. For projects that require moderate durability and cost-efficiency over a relatively short period, galvanized grate is a practical choice.

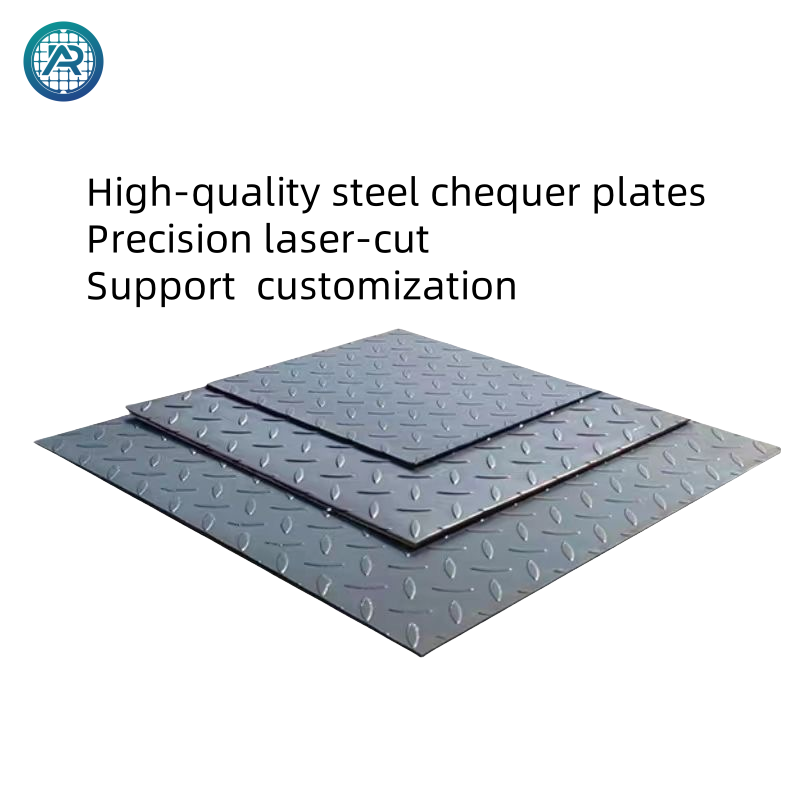

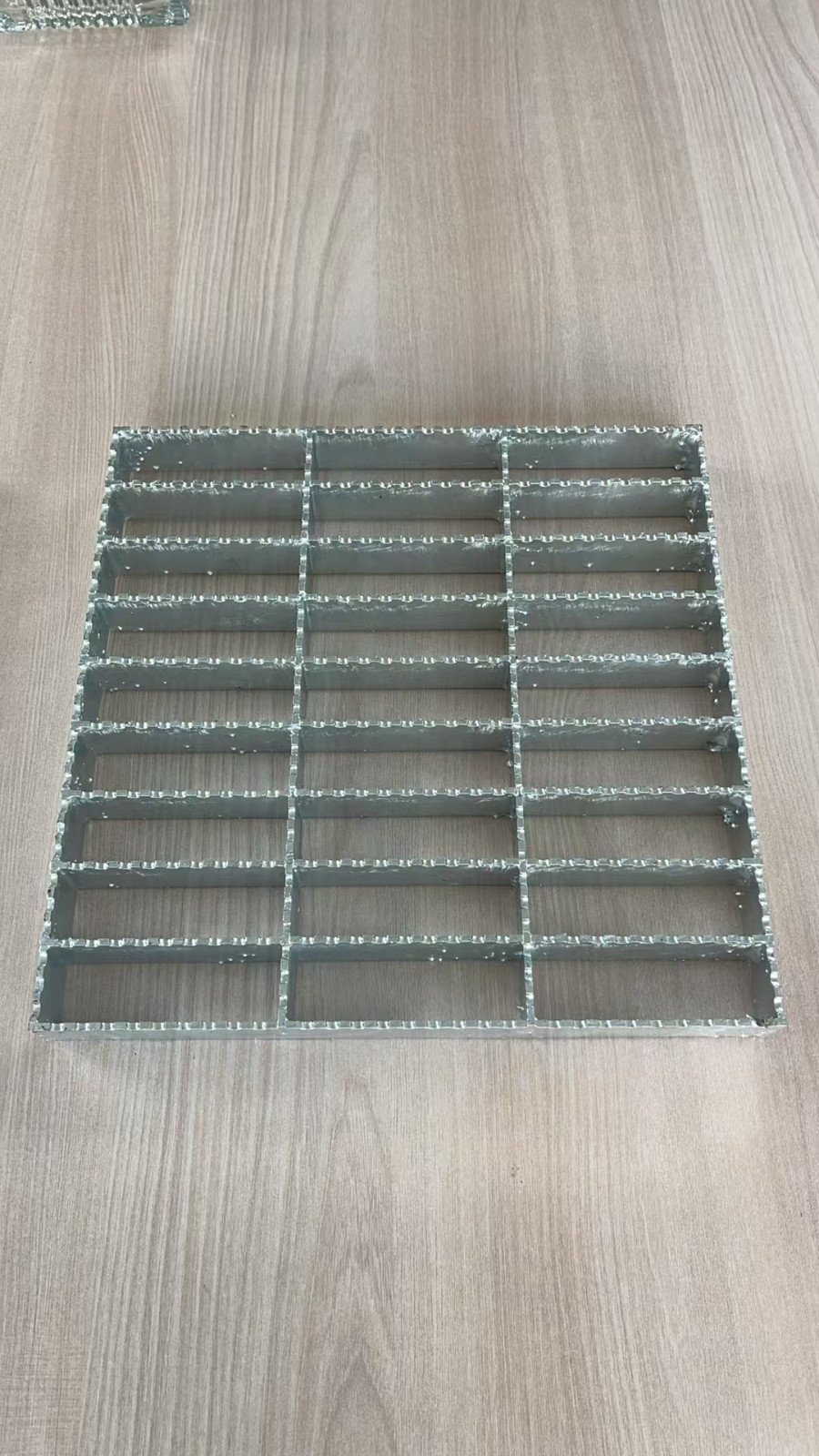

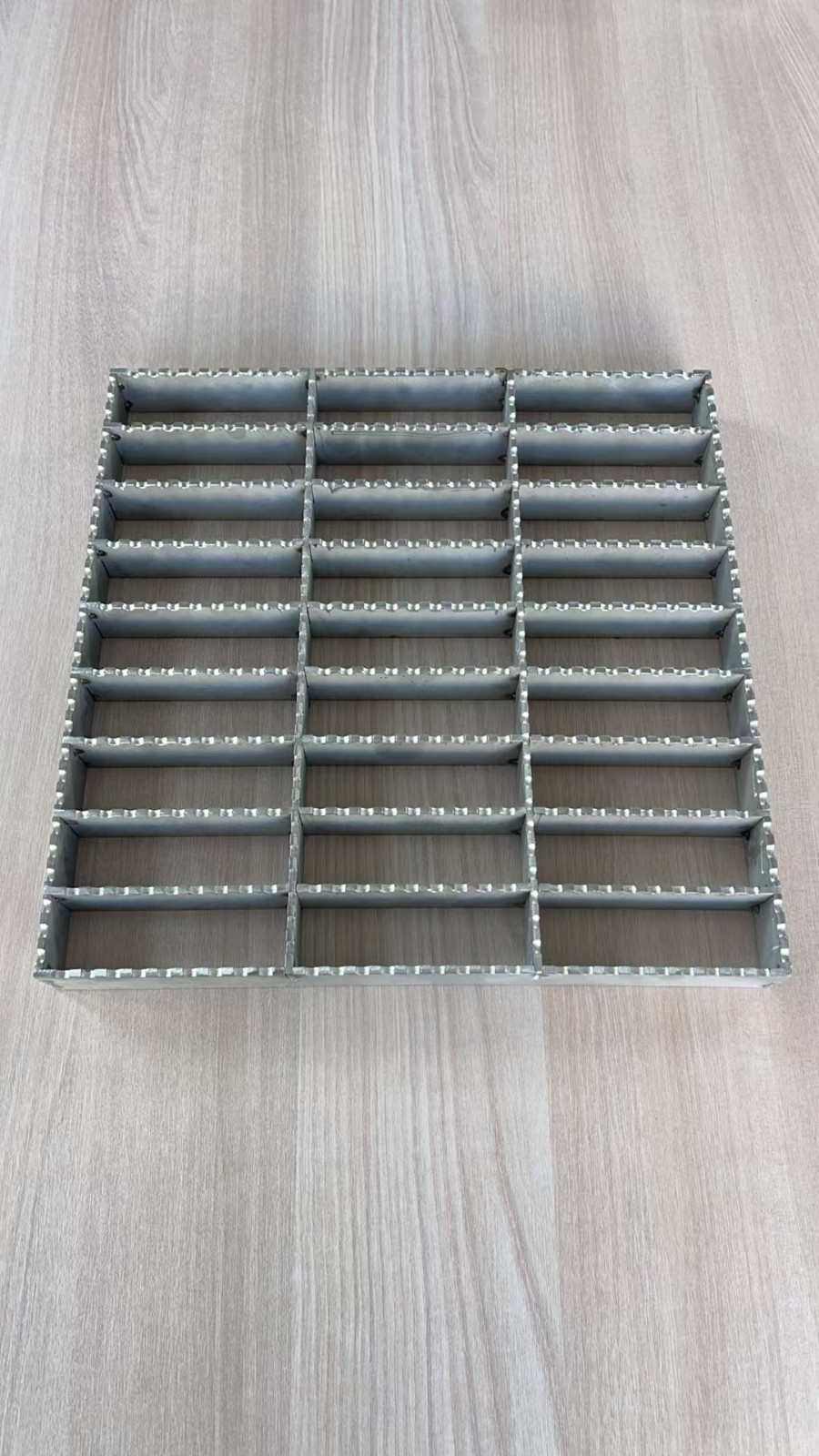

2. stainless steel grate: The Premium, Long-Lasting Option

stainless steel grate is made from corrosion-resistant steel alloys, such as 304 or 316 stainless steel. It is widely used in applications that require high strength and resistance to corrosion. stainless steel grate offers superior performance in harsh environments and is an ideal choice for projects with demanding specifications.

stainless steel grate offers significantly better corrosion resistance than galvanized grate. Even in harsh environments such as high humidity, marine climates, or chemically aggressive areas, stainless steel grate can maintain its structural integrity for much longer without degradation. In environments such as chemical plants or coastal areas, stainless steel grate is often the only viable option.

2.2 Long-Term Cost Effectiveness

While stainless steel grate is more expensive initially, its longevity and minimal maintenance requirements make it a cost-effective choice in the long run. In extreme conditions, galvanized grate may need frequent replacement or repair, but stainless steel grate can last for several decades with little or no maintenance. Over the course of a project’s lifespan, stainless steel grate may provide a lower total cost of ownership.

2.3 Aesthetic Appeal

stainless steel grate is known for its sleek, shiny appearance. Its smooth surface and uniform color give it a modern, high-end look, making it suitable for architectural projects that require aesthetic appeal. In commercial properties, luxury hotels, and high-end office buildings, stainless steel grate not only fulfills functional requirements but also adds to the visual quality of the space.

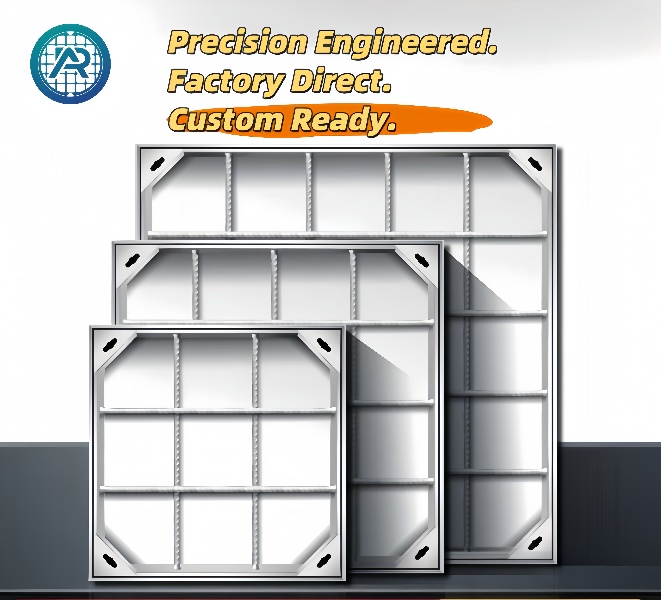

3. Comparing the Two: Application Scenarios

galvanized grate Applications:

Budget-Conscious Projects: Ideal for residential buildings, small commercial projects, or temporary facilities where cost is a primary concern.

Mild Corrosive Environments: galvanized grate works well in areas like urban drainage systems, pedestrian walkways, or factory warehouses where corrosion is not a significant threat.

Medium-Term Usage: Suitable for projects where the grating's service life is expected to be 10 years or less, and regular maintenance is feasible.

stainless steel grate Applications:

Harsh, Corrosive Environments: Perfect for areas exposed to sea air, chemical environments, or extreme conditions where corrosion is a major concern.

High-End Architectural Projects: stainless steel grate is used in luxury buildings, shopping malls, hotels, and office complexes that require both functionality and aesthetic appeal.

Long-Term Durability: Best suited for infrastructure projects like airports, ports, and chemical plants that require a high level of durability and minimal maintenance.

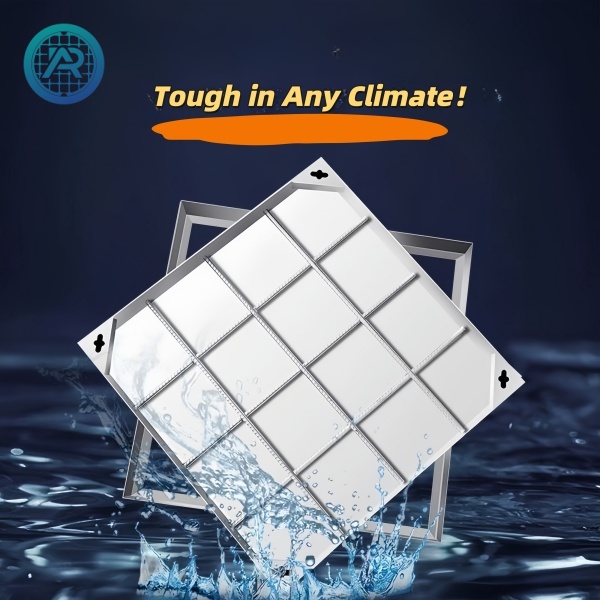

4. Forward-Looking Considerations: Sustainability and Environmental Impact

As the construction industry places more emphasis on sustainability and environmental impact, the choice of materials is also shifting toward greener, more eco-friendly options. stainless steel grate performs well in this area due to its high recyclability, making it a more sustainable material. In contrast, the zinc layer in galvanized grate, if not properly disposed of, may pose environmental concerns. As regulations around sustainability become stricter, stainless steel grate may become a more popular choice for eco-conscious projects.

5. Conclusion

Both galvanized grate and stainless steel grate offer distinct advantages depending on the project’s requirements. galvanized grate excels in cost-effectiveness, ease of maintenance, and moderate environments, making it ideal for budget-conscious or short-term projects. On the other hand, stainless steel grate offers superior corrosion resistance, aesthetic appeal, and long-term durability, making it the preferred choice for high-end, demanding applications.

Decision-makers in the construction industry should carefully evaluate the specific needs of their projects, considering factors such as budget, environmental conditions, and the required lifespan of the grating. By understanding the strengths and limitations of each material, it is possible to make an informed choice that maximizes both performance and value for the long term.

Ultimately, whether opting for galvanized or stainless steel grate, the key is to match the material to the project’s specific requirements, ensuring optimal performance, longevity, and cost-effectiveness. As the industry continues to evolve, the use of these materials will remain integral to building safer, more durable, and more sustainable infrastructure.