As global concerns about environmental protection and sustainable development continue to increase, the construction industry is also constantly exploring more environmentally friendly and sustainable materials and technologies. Grating products, as an indispensable component of building infrastructure, are widely used in various fields such as drainage systems, traffic pavements, industrial platforms, and more. Traditional grating materials such as steel and aluminum alloy, while possessing strong load-bearing capabilities, have gradually attracted attention for their negative environmental impacts during production, use, and disposal. With the rise of the green building concept, more and more environmentally friendly and sustainable grating materials have entered the market, providing the construction industry with more eco-friendly options. This article will explore the environmental friendliness of grating products and their sustainable development pathways, analyzing how innovative material selection and production processes can drive the green transformation of the grating industry.

Environmental Impacts of Traditional Grating Materials

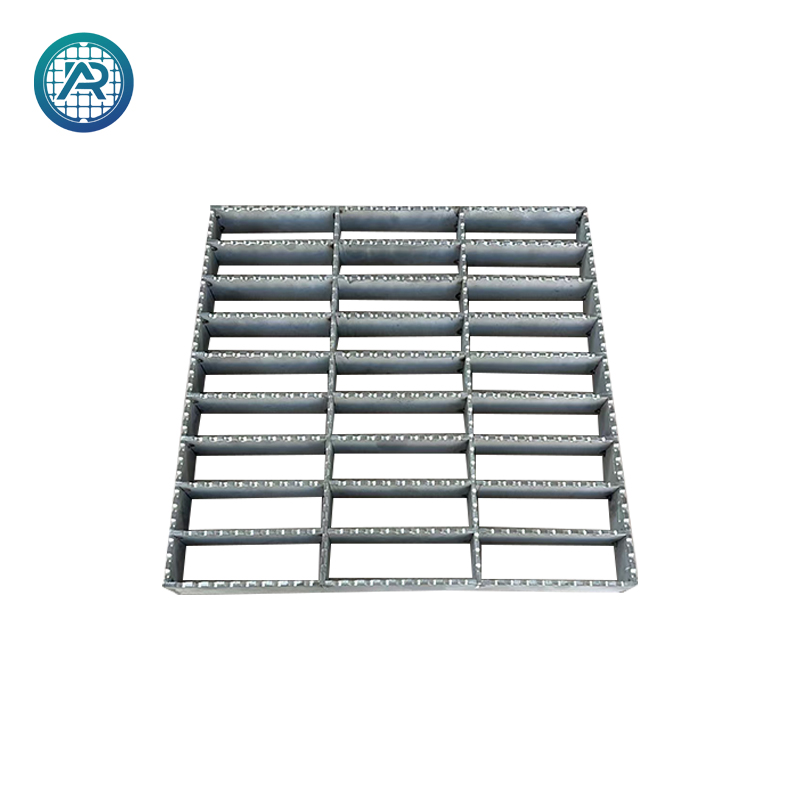

Traditional grating materials such as steel and aluminum alloy are widely used in the construction field, offering strong structural load-bearing capacity and durability. However, the production processes of these materials pose significant environmental pressures.

High Energy Consumption in Steel and Aluminum Alloy Production: The production processes for steel and aluminum alloy are complex and require substantial energy, especially as steel smelting often relies on fossil fuels such as coal, directly resulting in significant carbon dioxide emissions. The production process of aluminum alloy is also energy-intensive, with the mining and smelting of bauxite having a noticeable impact on the environment.

Resource Consumption and Waste Generation: The raw materials for steel and aluminum alloy require substantial mining of ores, which not only consumes vast natural resources but also leads to environmental damage, such as land desertification and vegetation destruction. Furthermore, when the service life of steel and aluminum alloy ends, if they are not effectively recycled and disposed of, the waste will pose a significant environmental burden.

Therefore, finding more environmentally friendly and sustainable grating materials has become an important direction for industry development.

Innovations in Environmentally Friendly Grating Materials

To address the environmental issues posed by traditional grating materials, many new eco-friendly materials have emerged, particularly plastics, composites, and recycled aluminum alloys. These materials not only have a lower environmental burden but also rival traditional materials in performance.

Plastic and Composite Grating

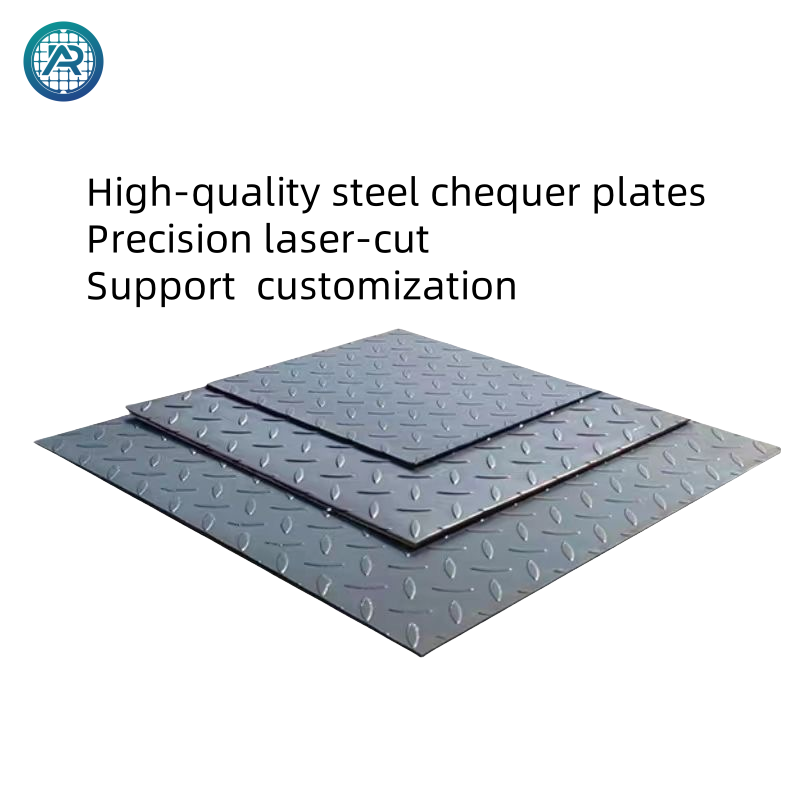

Plastic grating products, such as fiberglass reinforced plastic (FRP) grating, polypropylene (PP) and polyethylene (PE) grating, are becoming the preferred materials in an increasing number of projects. They support environmentally friendly buildings with their lightweight, corrosion-resistant, and recyclable characteristics.

Low Carbon Footprint: Compared to the smelting process of traditional metal materials, the production processes of plastics and composites consume significantly less energy. Furthermore, many plastic grating materials are made from recycled plastics, reducing resource consumption and carbon dioxide emissions from the source.

Durability and Long Lifespan: Plastic grating materials exhibit strong corrosion resistance and UV resistance, enabling long-term use in harsh environments and reducing the frequency of replacements, thereby minimizing resource waste.

Recyclability: Many plastic gratings can be recycled at the end of their service life, processed, and reintroduced into production, reducing the environmental burden of waste.

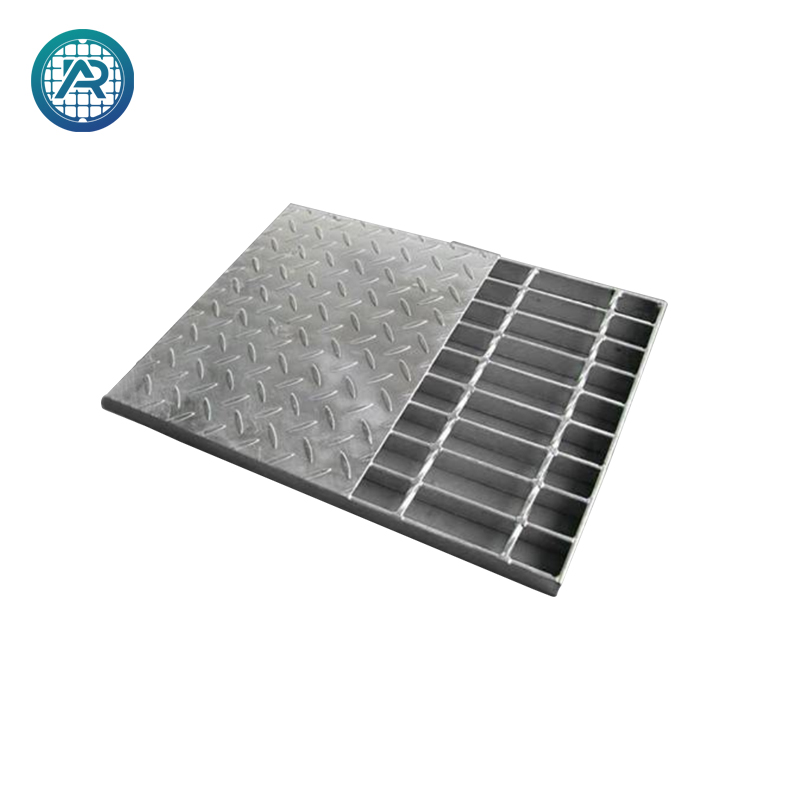

Recycled Aluminum Alloy Grating

For applications requiring metal grating, recycled aluminum alloy has emerged as a more environmentally friendly alternative to primary aluminum alloy. By using recycled aluminum alloy for production, energy consumption and carbon emissions during the production process can be significantly reduced.

Environmental Benefits: The energy consumption for recycling aluminum is only about 5% of that for producing primary aluminum, significantly reducing energy consumption and greenhouse gas emissions. Moreover, recycled aluminum alloy maintains excellent mechanical properties while effectively reducing the environmental impact of ore mining.

Green Manufacturing Processes

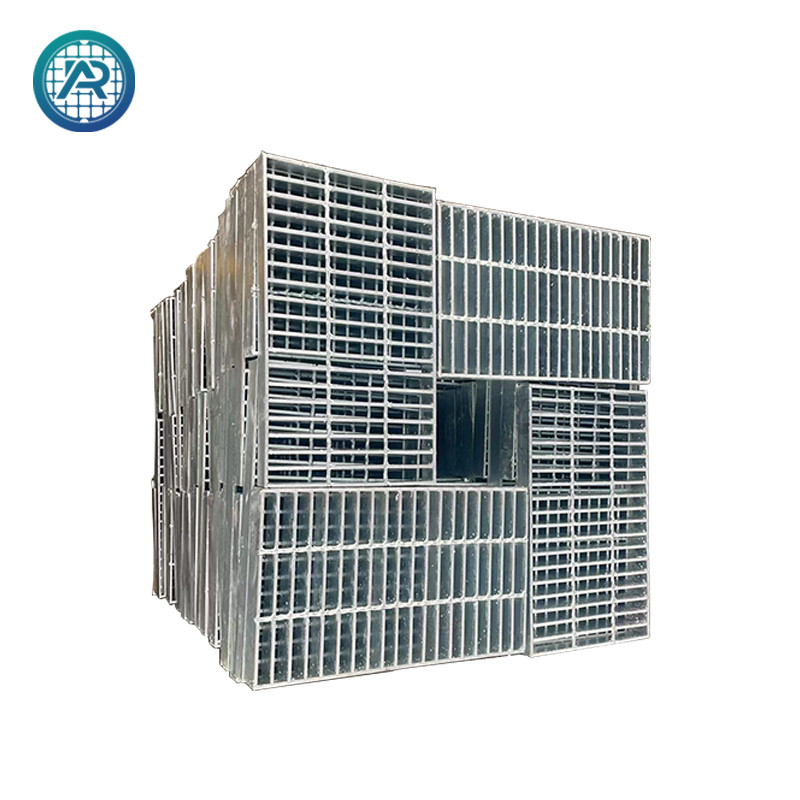

In addition to material innovations, the manufacturing processes of grating products are also crucial for achieving sustainable development. By optimizing production processes, improving resource utilization, and reducing waste and emissions, modern grating product manufacturing is moving towards a greener direction.

Energy Saving and Emission Reduction: With technological advancements, some grating manufacturers are adopting more energy-efficient equipment and production methods. For example, the use of high-efficiency electric furnaces and low-emission technologies to reduce energy consumption and exhaust emissions.

Water Resources and Waste Management: Modern production processes also focus on the recycling of water resources and the classified treatment of waste. Many manufacturers have achieved closed-loop recycling of water resources during production, greatly reducing water waste. Additionally, waste materials during production, such as metal residuals and plastic scraps, are effectively recycled and reused, minimizing environmental impact.

Localized Production: To reduce carbon emissions during transportation, more and more manufacturers are establishing production bases in major market regions, enabling localized production of materials and products. This not only reduces the carbon footprint of transportation but also supports the development of local economies.

Sustainability in Design and Use

During the design phase of grating products, sustainability considerations are equally crucial. Modern grating product designs increasingly emphasize modularity, long lifespan, and ease of maintenance, thereby reducing the environmental burden.

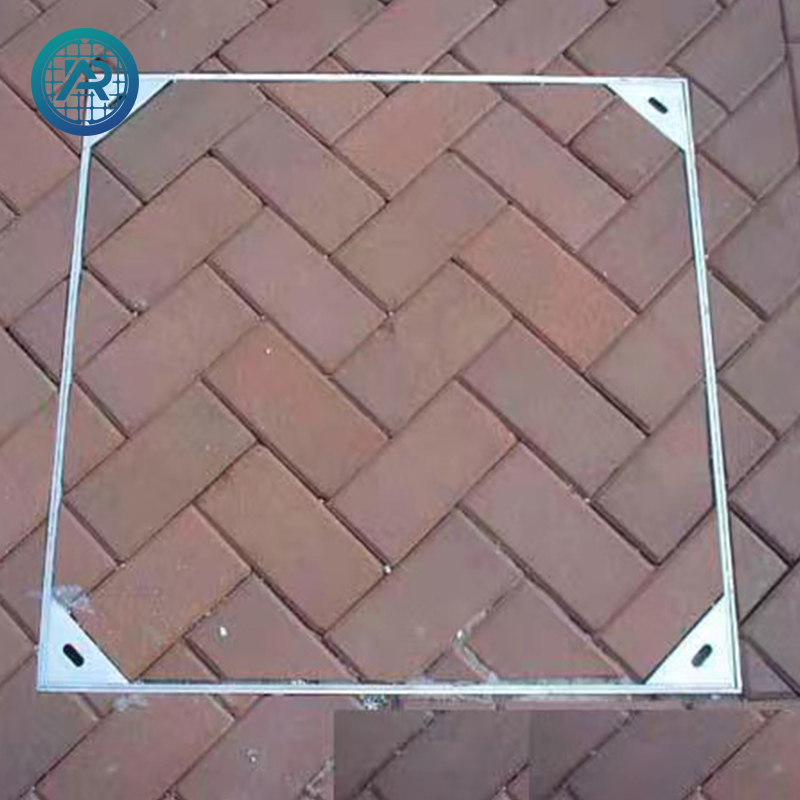

Modular Design: Modern grating designs tend towards modular systems, making replacements and repairs more convenient. This design approach reduces unnecessary resource consumption, especially in applications requiring frequent replacements or repairs.

Long-term Use and Maintenance: By enhancing product durability and ease of maintenance, modern gratings can extend their service life, reducing resource waste and environmental pollution caused by frequent product replacements.

Conclusion: Advancing the Future of Green Buildings

As global concerns about sustainable development and environmental issues continue to grow, the green transformation of the grating product industry is becoming an important direction for future development in the construction industry. From the selection of environmentally friendly materials to the application of green production processes, to the integration of sustainable design concepts, modern grating products are moving towards a greener and more sustainable direction.

By choosing environmentally friendly materials, innovating production processes, and enhancing design sustainability, grating products can not only meet the functional needs of the construction industry but also play a crucial role in reducing resource consumption, lowering carbon emissions, and improving recycling rates. With continuous technological advancements and the deepening of environmental awareness, the sustainability of grating products will provide a solid foundation for building a greener, lower-carbon future.