Recessed Drain Covers: Design and Functional Optimization

Manhole covers are a vital part of urban infrastructure, supporting road traffic, public safety, and drainage systems. With technological advancements, traditional flat manhole covers are increasingly being replaced by recessed covers. Their unique structural design and functional advantages significantly enhance urban infrastructure's safety, durability, and environmental sustainability.

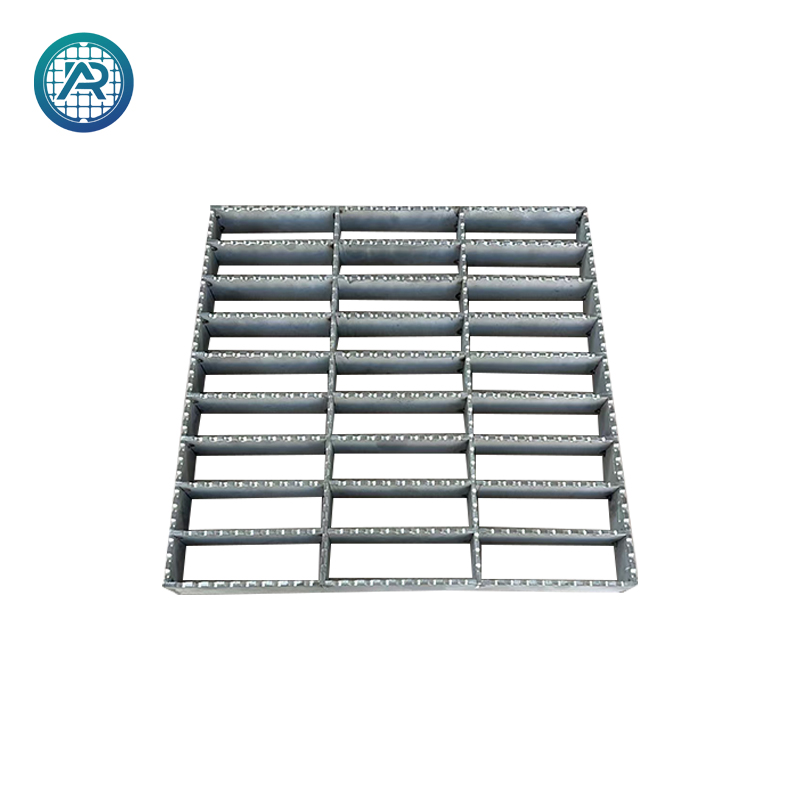

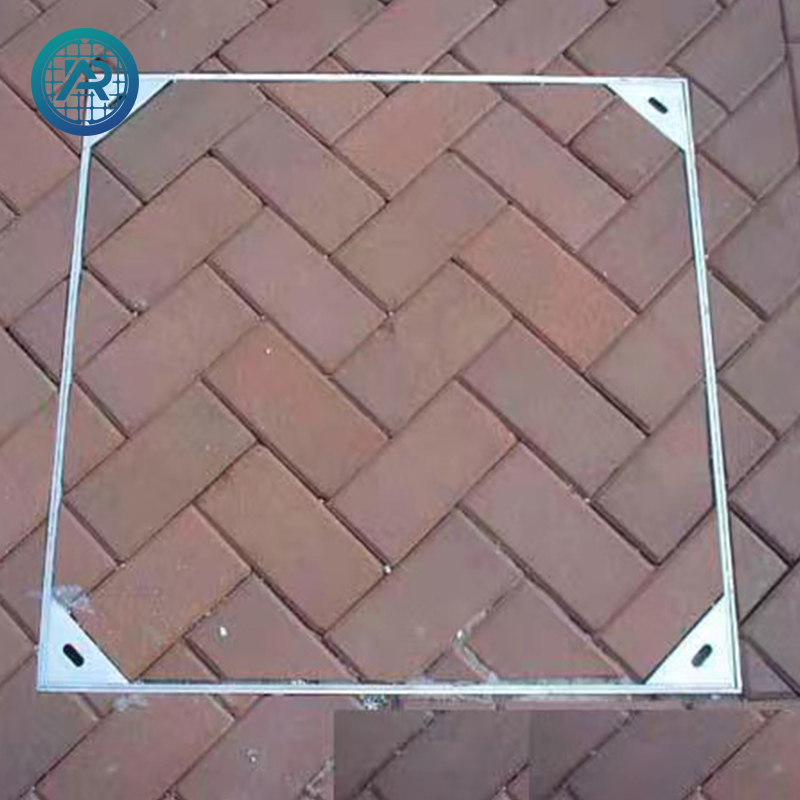

1. Structural Advantages of Recessed Drain Covers

Design Philosophy and Functionality

The design of recessed drain covers effectively reduces the pressure on the surrounding ground, improving stability and load-bearing capacity. The recessed structure disperses pressure when bearing heavy loads, preventing cracking or damage caused by excessive force.

Comparison with Flat Manhole Covers

Compared to traditional flat covers, recessed covers offer clear structural benefits, including:

Enhanced load-bearing capacity

Greater durability

Prevention of ground subsidence around the cover

2. Material Selection and Durability

2.1 Analysis of Common Materials

The choice of materials for recessed drain covers is crucial for their performance, durability, and environmental adaptability. Common materials include cast iron, composite materials, and stainless steel, each with unique characteristics and applications:

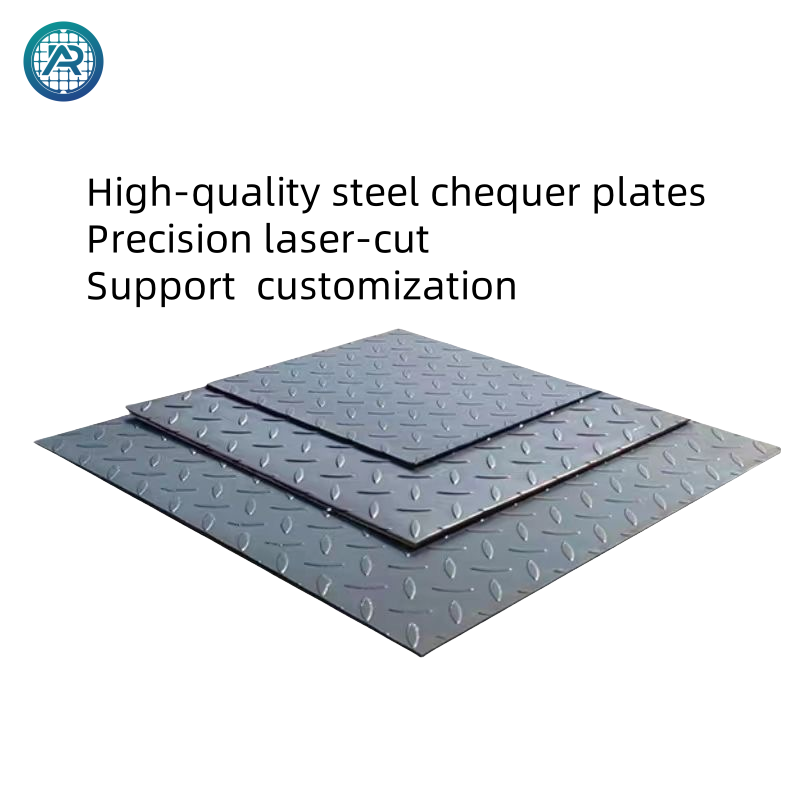

Cast Iron Covers

Strength and Durability: Cast iron is a traditional and widely used material known for its excellent compressive strength. It is particularly suitable for high-traffic roads and highways, enduring heavy vehicle loads without breaking.

Applications: Commonly used in urban roads, industrial zones, and high-traffic areas, cast iron covers remain stable and reliable over long-term use.

Drawbacks: Cast iron covers are heavy and prone to rust, requiring regular maintenance and anti-corrosion treatment. Prolonged use can lead to corrosion or deformation.

Composite Covers

Lightweight and Eco-Friendly: Composite covers (e.g., reinforced fiberglass or polymers) are lightweight, high-strength, and corrosion-resistant, making them a sustainable alternative to traditional materials. Their weight is roughly one-third that of cast iron, simplifying handling and installation.

Applications: Suitable for areas with lower weight demands, such as pedestrian pathways, bike lanes, or parks.

Drawbacks: Composite covers may be less durable in heavy-load environments compared to cast iron.

Stainless Steel Covers

Corrosion Resistance: Stainless steel covers excel in resisting corrosion, making them ideal for humid, rainy, or coastal areas. They maintain stable performance under exposure to salt and moisture.

Applications: Commonly used in urban drainage systems, industrial zones, and areas exposed to harsh weather conditions like coastal cities and chemical industrial parks.

Drawbacks: Stainless steel is more expensive, and its load-bearing capacity may require reinforcement for heavy-load applications.

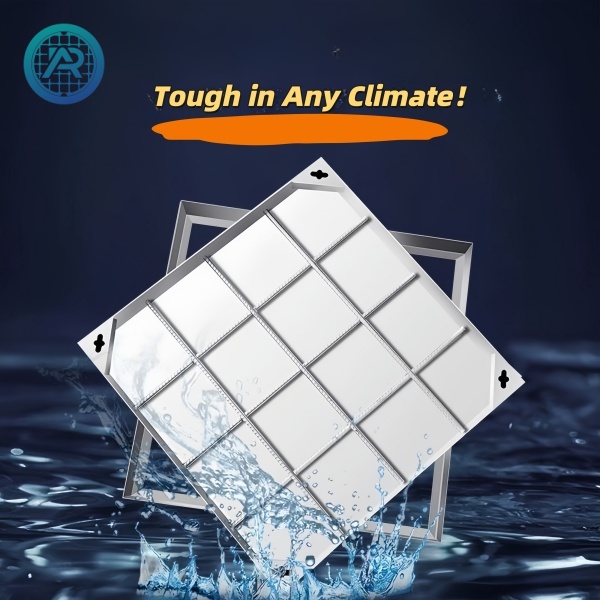

2.2 Environmental Adaptability of Materials

Manhole cover materials must also meet the specific environmental requirements of their location. Climate conditions, traffic loads, and other factors directly impact material selection.

Cold Regions – Freeze Resistance

In cold climates, manhole covers are subject to frequent freeze-thaw cycles. Cast iron and stainless steel perform well in these conditions, often reinforced with anti-freeze alloys to prevent cracking. For instance, in regions like Russia and Canada, thicker or specially alloyed cast iron is commonly used.

Tropical Regions – Corrosion Resistance

In high-temperature, humid, and salty environments, corrosion poses a significant challenge. Composite and stainless steel covers are well-suited for these regions due to their anti-corrosion properties. For example, in Southeast Asia or Mediterranean coastal cities, these materials effectively withstand high humidity and salinity.

Urbanized Areas – High Traffic Load Requirements

In densely populated urban centers, manhole covers must handle heavy traffic. Cast iron is ideal for such areas due to its strength, while composite covers are better suited for lighter load areas like pedestrian zones.

3. Load-Bearing Capacity and Safety

3.1 Compression and Impact Testing

The load-bearing and impact resistance of recessed drain covers are fundamental performance indicators, especially with increasing traffic flow and vehicle weight.

Compression Strength: The recessed structure disperses ground pressure, reducing localized stress and enhancing load-bearing capacity. Covers undergo rigorous compression testing to ensure they meet traffic demands without deforming or cracking.

Impact Resistance: Recessed covers must also withstand sudden impacts, such as heavy machinery or trucks passing over them. Optimizing the recessed design and using high-strength composite materials or alloy cast iron improves impact resistance, ensuring durability.

3.2 Safety Features and Anti-Theft Measures

Safety is a critical consideration for manhole covers, particularly in urban environments prone to theft and damage.

Anti-Theft Design: Special locking mechanisms or intelligent anti-theft systems effectively prevent unauthorized removal. Traditional measures include lockable covers requiring specialized tools for opening, while modern solutions, such as RFID chips or smart sensors, provide real-time monitoring of manhole cover status.

Damage Monitoring and Alerts: Smart covers equipped with sensors can detect damage or displacement. Alerts are sent to management systems, enabling timely repairs and reducing accident risks.

4. Drainage and Anti-Waterlogging Features

4.1 Drainage Design

Recessed drain covers excel in drainage, particularly in rainy or humid environments. Their unique shape allows rainwater to flow quickly into the drainage system, preventing pooling and ensuring safer roads.

4.2 Innovations in Anti-Waterlogging Design

In certain scenarios, waterlogging around manhole covers may still occur due to blocked pipes or improper design. Innovative solutions include:

Improved Design: Increasing the number or depth of drainage holes enhances efficiency, ensuring smooth water flow.

Smart Drainage Systems: Sensors installed on covers can monitor water levels in real time, improving drainage efficiency and enabling more effective urban management.

Conclusion

Recessed drain covers, with their unique design and versatile material options, are an indispensable part of modern urban infrastructure. Future development will increasingly rely on sustainable materials and smart technologies. Lightweight, eco-friendly composites will further enhance usability, while IoT integration and sensor technology will enable real-time monitoring and intelligent management. As cities face growing demands for complex infrastructure, recessed drain covers will continue to play a crucial role in promoting public safety, environmental sustainability, and urban resilience.