1. Traditional vs. Modern: The Evolution from Cast Iron to Composite Manhole Covers

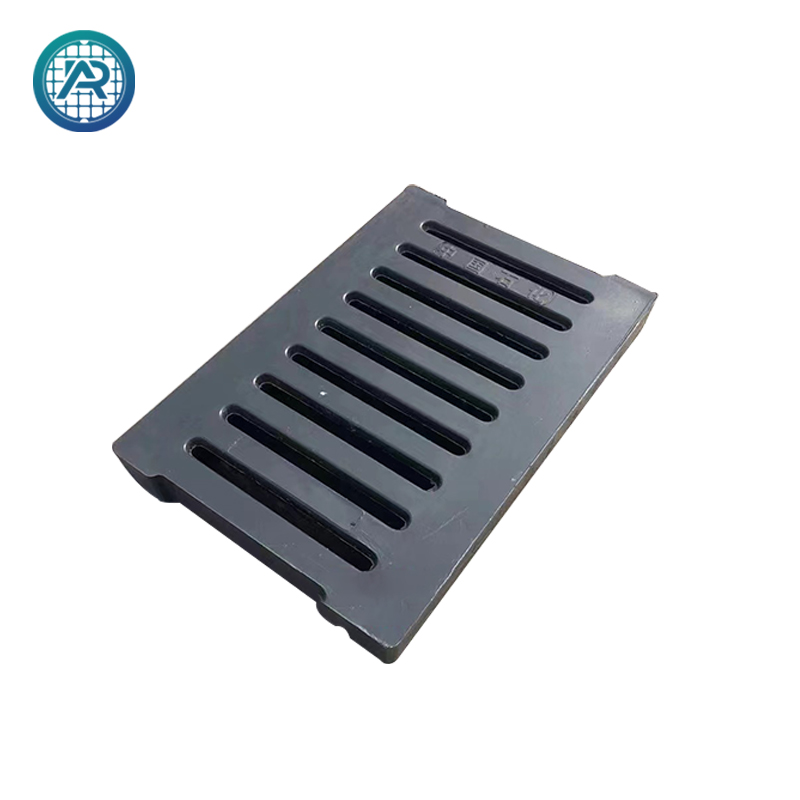

Traditionally, cast iron has been the main material for manhole covers due to its high strength, durability, and moderate cost. However, cast iron covers also have significant drawbacks, such as excessive weight, which makes installation and maintenance challenging, and susceptibility to theft. As urban infrastructure demands evolve, there is a need for manhole covers that are more resistant to corrosion, weathering, and aesthetic requirements. In this context, composite manhole covers have emerged as a prominent alternative. Compared to cast iron, composite covers are lightweight, corrosion-resistant, non-conductive, and theft-resistant. Today, they are widely used in municipal, road, and landscaping projects, representing a forward direction in the industry.

2. Composite Manhole Covers: A Win-Win in Lightweight and High Strength

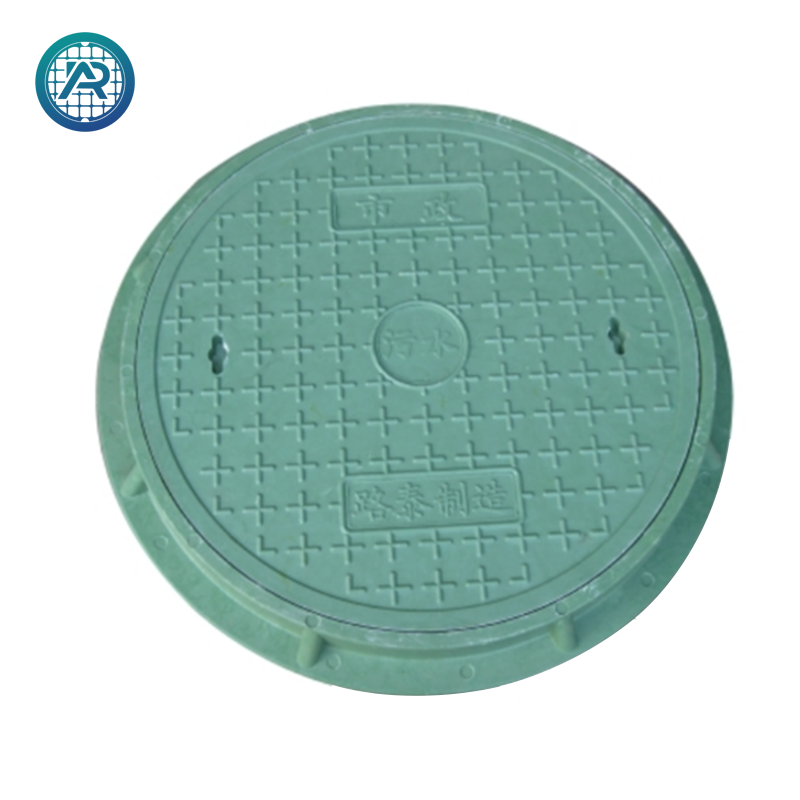

The advent of composite manhole covers has revolutionized the industry, especially in terms of achieving a balance between lightweight design and high strength. Composites often use materials such as fiberglass and resin, formed through specific processes. Compared to cast iron, composite covers are significantly lighter, typically weighing only half or less, which reduces installation and transportation costs. Lightweight design also facilitates maintenance, minimizing the risk to workers during handling.

This lightweight feature does not compromise strength. Many composite materials now match or even surpass traditional cast iron in terms of strength and hardness. For example, covers made by combining high-strength fiberglass with specialized resins can withstand high pressure and impacts, making them suitable for use on highways and other areas with stringent load requirements.

Composite covers also offer excellent theft resistance. Traditional cast iron covers, due to their metal content, are often targeted for theft; in contrast, composite covers have no recycling value, effectively eliminating this risk. Additionally, composite covers can be customized with anti-slip surfaces to enhance the safety of vehicles and pedestrians. Their non-conductive nature prevents the risk of electric shock in severe weather, making them particularly suitable for power-dense areas.

The manufacturing process of FRP manhole covers is also environmentally friendly. Composite materials can often be produced through compression molding, injection molding, and other techniques that generate minimal waste, and many composites can be made from renewable resources. With advances in technology, the durability and sustainability of composite covers will continue to improve, supporting smart city initiatives and environmental goals.

3. Environmental Sustainability: The Green Revolution in Manhole Cover Materials

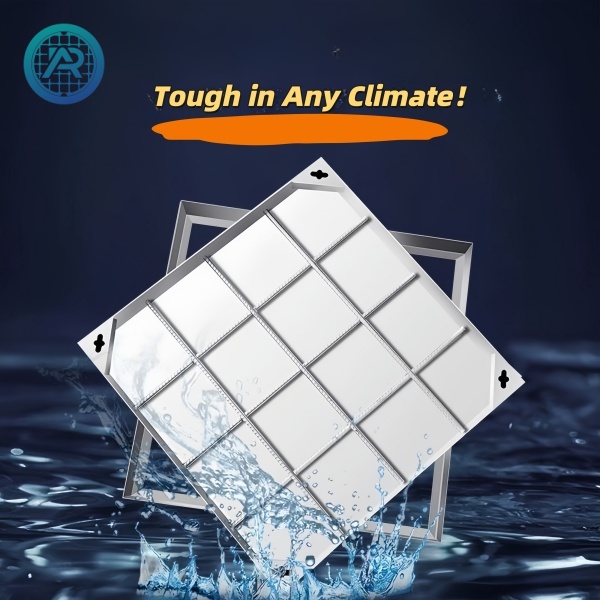

Amid global advocacy for environmental protection and sustainable development, the eco-friendliness of manhole cover materials is receiving growing attention. Traditional cast iron covers require significant resources, and the mining, smelting, and casting processes release large amounts of CO₂ and waste gas. In contrast, composite covers offer clear environmental benefits. They can be made from renewable resources, even recycled plastics and resins, and their low-energy production process reduces dependence on natural resources.

In addition to sustainable material sources, composite manhole covers also offer environmental advantages through extended service life. Composite materials resist corrosion and aging, particularly in harsh environments like acid rain and coastal areas, ensuring long-term use and reducing resource consumption from frequent replacements. Even when discarded, composite covers can often be partially recycled, reducing environmental impact throughout their lifecycle.

The application of eco-friendly composite covers also advances the green transformation of urban infrastructure. For example, in stormwater and sewage systems, covers need to resist corrosion and be non-toxic to avoid secondary environmental pollution. Composite covers, being non-toxic and highly sealable, effectively block wastewater leakage and gas emissions. Thus, eco-friendly covers not only enhance urban environmental quality but also reduce the costs associated with urban pollution management.

With technological advancements, future manhole cover materials may trend toward biodegradable composites. Under certain conditions, these materials can gradually degrade, reducing long-term environmental impact. The production process of green covers is also improving, with innovations such as low-temperature curing resins and reduced chemical solvents, further enhancing eco-friendliness. The development of eco-friendly FRP manhole covers aligns with green city-building goals and points to a sustainable future for the industry.

4. Smart Material Manhole Covers: New Anti-Theft and Monitoring Functions

As smart city projects advance, the selection of materials for smart manhole covers has become a crucial topic. Traditional covers serve mainly to secure the opening, protecting roads and pedestrians, but smart covers can achieve more through embedded sensors or smart locks. Smart materials for manhole covers must allow for embedded sensors, withstand corrosion, water, and high temperatures, and ensure sensor stability.

For anti-theft purposes, smart manhole covers often integrate RFID chips or IoT modules to monitor their status in real-time. If a cover is moved without authorization, an alert can be sent automatically. This feature reduces theft risk while enabling authorities to monitor cover location and status for more precise maintenance and management.

5. Future Outlook: The Trend of 3D Printing and Customization in Manhole Cover Materials

With the rapid development of 3D printing, customized designs for manhole cover materials are becoming feasible. Traditional manufacturing is limited by molds and production processes, often resulting in standardized, mass-produced covers. However, 3D printing technology allows for more flexible design options. For instance, high-polymer composites or ceramic-based composites can be 3D printed into covers with more complex structures and enhanced performance.

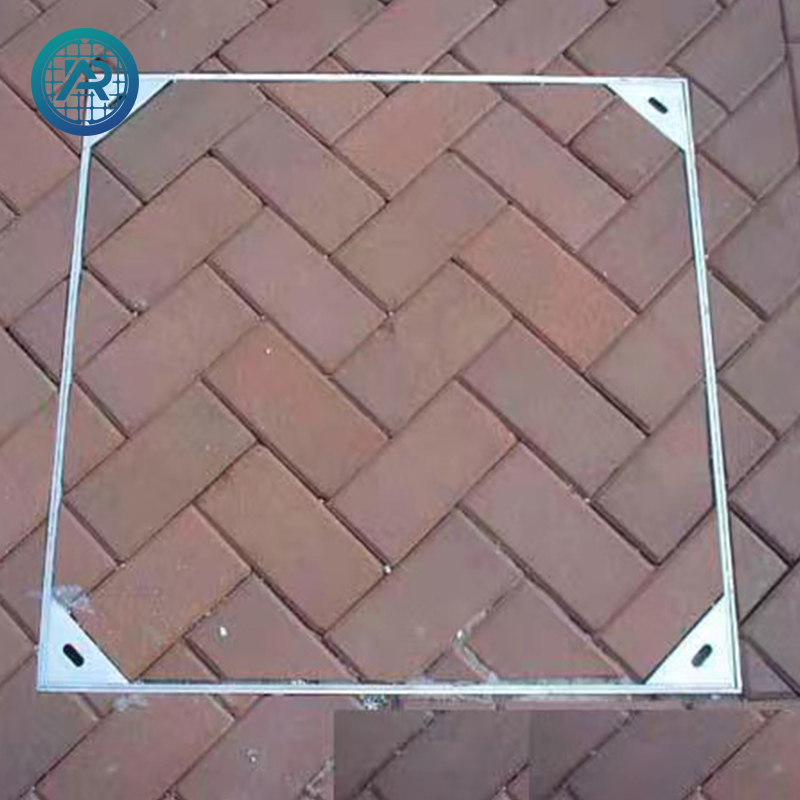

3D-printed covers have improved strength, toughness, and load-bearing capacity while maintaining a lightweight structure. Additionally, 3D printing enables the customization of covers to suit different urban or environmental needs. Custom designs in color, texture, and shape can meet aesthetic demands, enhancing the functional and visual appeal of manhole covers. In cultural cities, for example, uniquely patterned covers add local character and beauty.

As the costs of 3D printing materials decrease and the technology advances, mass production of 3D-printed covers is likely to become viable. Demand for customized covers is expected to increase, especially in high-end residential, commercial, and tourism areas with high landscaping requirements. Combined with big data and IoT technologies, 3D-printed covers can integrate with urban management systems, enabling intelligent monitoring and management to support smart city construction.

In conclusion, 3D printing is opening new possibilities for manhole cover material innovation, driving the industry towards greater personalization and intelligence.