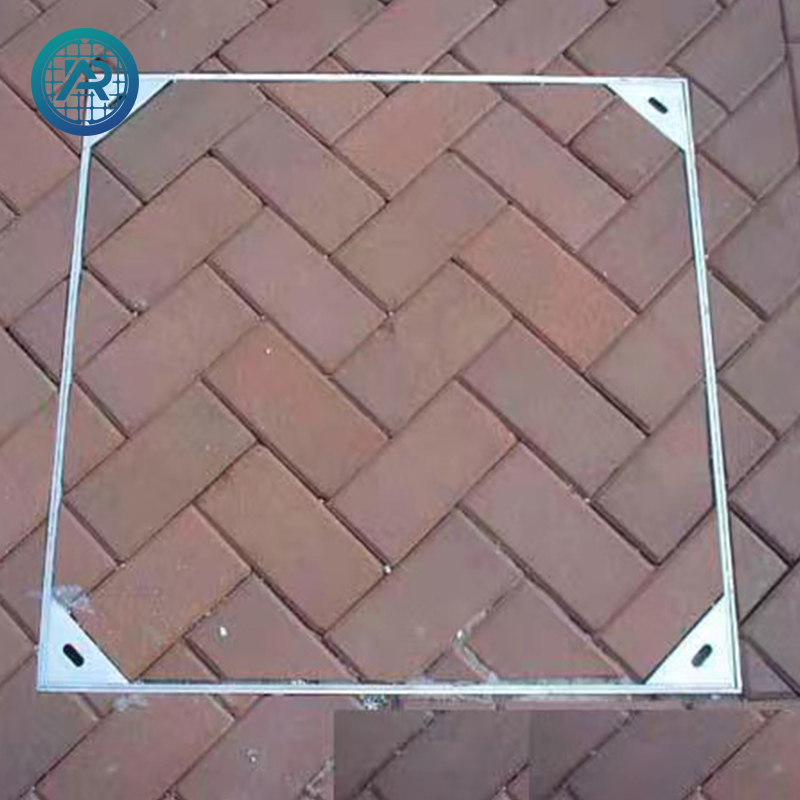

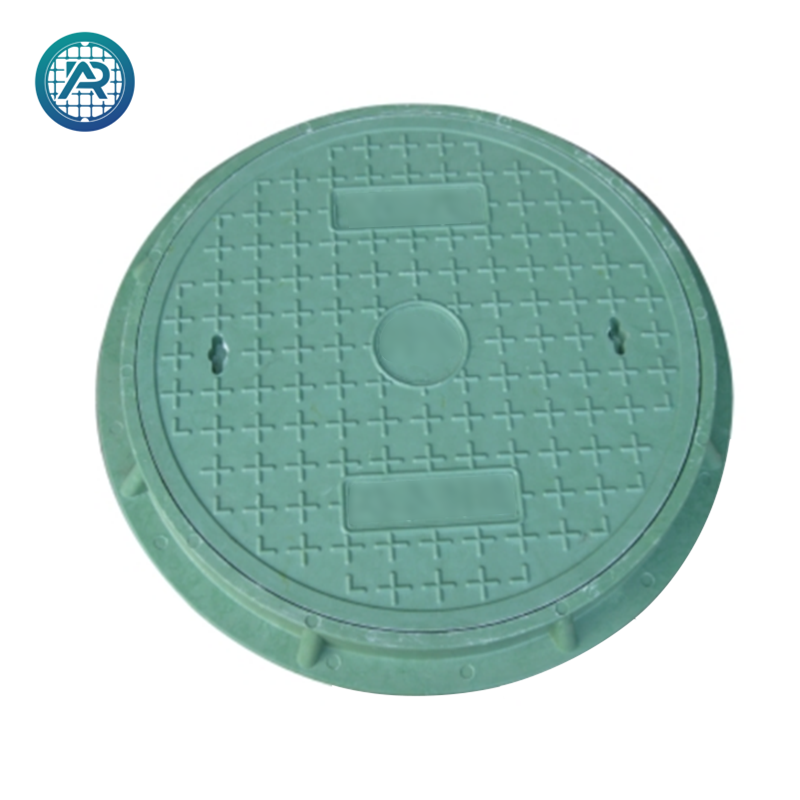

FRP manhole covers and frp chamber covers have revolutionized urban infrastructure with their unique combination of lightweight durability (30% lighter than cast iron), corrosion resistance (withstands pH 1-13 environments), and electrical insulation properties (dielectric strength ≥15kV/mm). This 2500-word guide explores the complete manufacturing journey of these composite marvels.

I. Material Selection & Preparation

Matrix Materials

Unsaturated Polyester Resin: Dominates 80% of FRP manhole cover production due to cost-effectiveness ($2.5-3/kg) and fast curing. Orthophthalic type for general use, isophthalic for chemical resistance.

Epoxy Resin: Used in premium frp chamber covers requiring ≤0.1% water absorption, especially in submarine cable chambers.

Reinforcement

FRP manhole cover: 4 layers of 600g/m² woven roving + 2 layers 450g/m² CSM

Frp chamber cover: 3 layers 800g/m² unidirectional fabric + 1 layer 300g/m² veil mat

E-glass Fiber: Standard choice, providing tensile strength of 1500-2000MPa.

Layer configuration:

Additives

Fire retardancy: Aluminum trihydrate (ATH) 50-60% loading for UL94 V-0 rating

UV protection: 2% titanium dioxide pigment

II. Mold Engineering

*Critical for achieving ≤0.5mm/m dimensional tolerance*

Mold Types

Cast steel molds for FRP manhole covers (500+ cycles lifespan)

CNC-machined aluminum molds for complex frp chamber covers

Surface Treatment

3-step polishing (400→800→1500 grit)

Semi-permanent PTFE release film application

III. Layup Process Breakdown

Step 1: Gel Coating

Spray 0.5mm thick isophthalic gel coat (80% resin + 20% filler) using HVLP guns at 60PSI. Cure until tack-free (40min @25℃).

Step 2: Structural Lamination

Hand lay-up sequence for FRP manhole cover:

Layer 1: 300g CSM (resin ratio 70%)

Layer 2: 600g 0/90° woven roving (resin 50%)

Repeat 4×, totaling 6.8kg/m² fiber content

Frp chamber cover specialized layup:

Radial fiber orientation around bolt holes

Foam core sandwich structure (20mm thickness)

Step 3: Vacuum Bagging (Optional)

Enhances fiber/resin ratio to 75:25, reducing voids <1%. Typical parameters:

Vacuum level: -29inHg

Duration: 90min

IV. Curing Science

Exothermic Control

Maximum exotherm ≤130℃ to prevent cracking

Use slow-cure MEKP (1.5% dosage) for thick-section FRP manhole covers

Post-Curing Schedule

Ramp: 2℃/min to 80℃

Hold: 4hrs for full crosslinking

V. Demolding & Machining

Ejection System

6-8 pneumatic ejector pins @ 80PSI

Draft angles: 3° minimum

CNC Trimming

Waterjet cutting @ 60,000PSI

Positional accuracy: ±0.2mm

VI. Quality Assurance Protocols

Mechanical Testing

IP68 waterproofness (1m water immersion ×24hrs)

15kV partial discharge test

400kN compression test (simulating 40-ton truck load)

250,000-cycle fatigue test @ 10Hz

FRP manhole cover:

Frp chamber cover:

Chemical Resistance

30% sulfuric acid (weight loss ≤1.2mg/cm²)

5% NaCl salt spray (ASTM B117)

90-day exposure to:

VII. Smart Manufacturing Trends

IoT-Enabled Covers

Embedded strain gauges for real-time load monitoring

RFID tags for asset management

Sustainable Production

30% recycled glass fiber content

UV-curing resins reducing VOC by 70%