1. What is FRP Manhole Cover?

FRP Manhole Cover (Fiberglass Reinforced Plastic Manhole Cover) represents a paradigm shift in urban infrastructure. By combining glass fibers with thermosetting resins (such as polyester or epoxy), this composite material achieves a unique synergy of strength, durability, and adaptability. Unlike traditional cast iron or concrete covers, frp man hole cover is engineered to address modern challenges—corrosion, theft, and sustainability—while seamlessly integrating with smart city frameworks.

2. Four Core Advantages of FRP Manhole Covers

2.1 Lightweight Design for Efficient Installation

The

density of FRP man hole cover(1.8-2.1 g/cm³) is just one-fourth that of steel,

enabling a single worker to handle covers weighing as little as 20-30

kg. This drastically reduces labor costs and installation time. For

instance, in the 2023 retrofit of Singapore’s Orchard Road drainage

system, the adoption of frp man hole cover cut deployment time by 45%, saving over $120,000 in labor expenses.

Technical Insight:

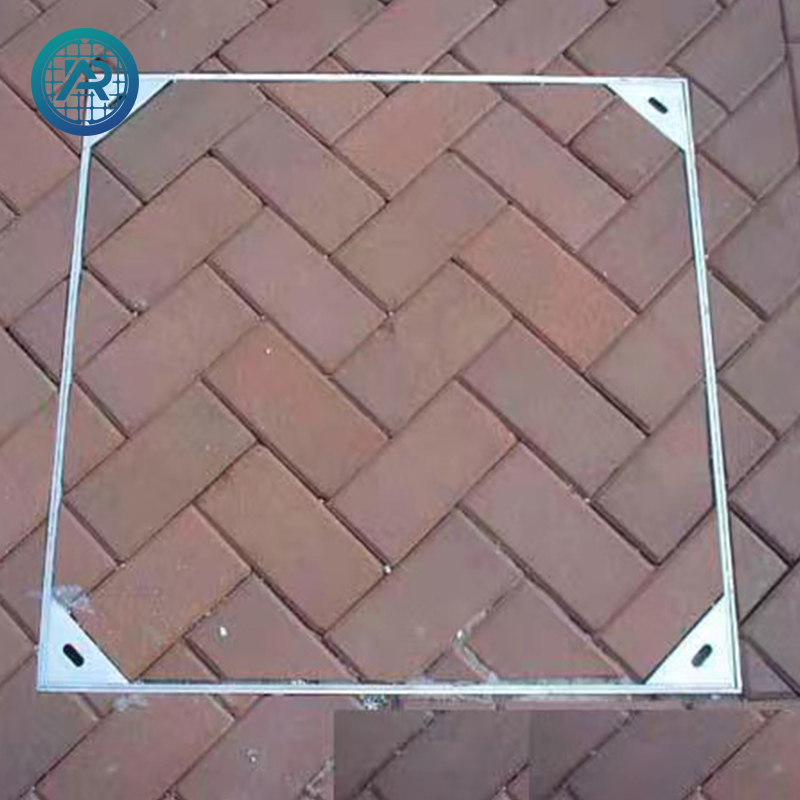

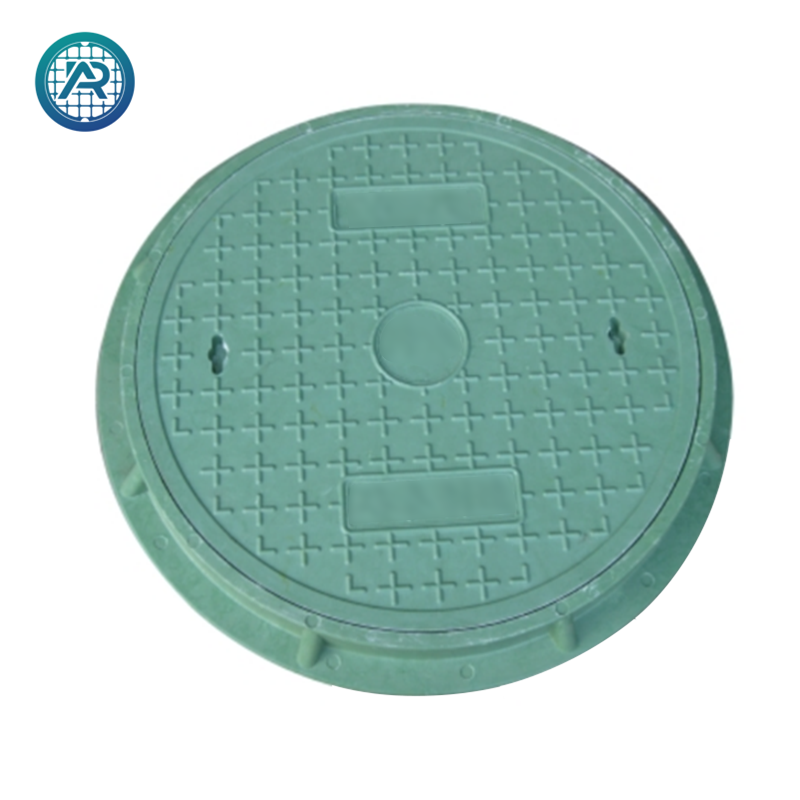

Modular Design: FRP manhole covers can be prefabricated into custom shapes (circular, square, or rectangular) to fit non-standard manholes, minimizing on-site adjustments.

Reduced Logistics Costs: A standard 20-foot container can hold 300 FRP covers versus 80 cast iron ones, slashing shipping expenses by 60% for overseas projects.

2.2 Corrosion Resistance with 30-Year Lifespan

FRP’s

immunity to rust, chemicals, and UV degradation makes it ideal for

extreme environments. In a 10-year field study conducted in Dubai’s

coastal zones, FRP manhole covers exposed to salt spray and 50°C heat showed zero structural degradation, outperforming stainless steel alternatives.

Case Study: Maldives’ Male City Waterfront Project

Challenge: High salinity (3.5% NaCl concentration) caused cast iron covers to corrode within 2 years.

Solution: Switching to frp man hole cover with anti-UV coating extended service life to 15+ years.

Cost Savings: Reduced replacement frequency saved the city $280,000 annually.

2.3 High Load-Bearing Capacity

Through

multi-axial fiber layering and resin infusion, FRP manhole cover achieves directional

strength tailored to traffic patterns. For example:

EN124 D400 (40-ton) Certification: Mandatory for airport taxiways. FRP man hole covers at London Heathrow’s Terminal 5 withstood 2 million+ aircraft wheel passes without deformation.

Dynamic Load Testing: ASTM C1577 simulations confirm FRP manhole covers fatigue resistance exceeds 10 million cycles at 25-ton loads.

Innovation Spotlight:

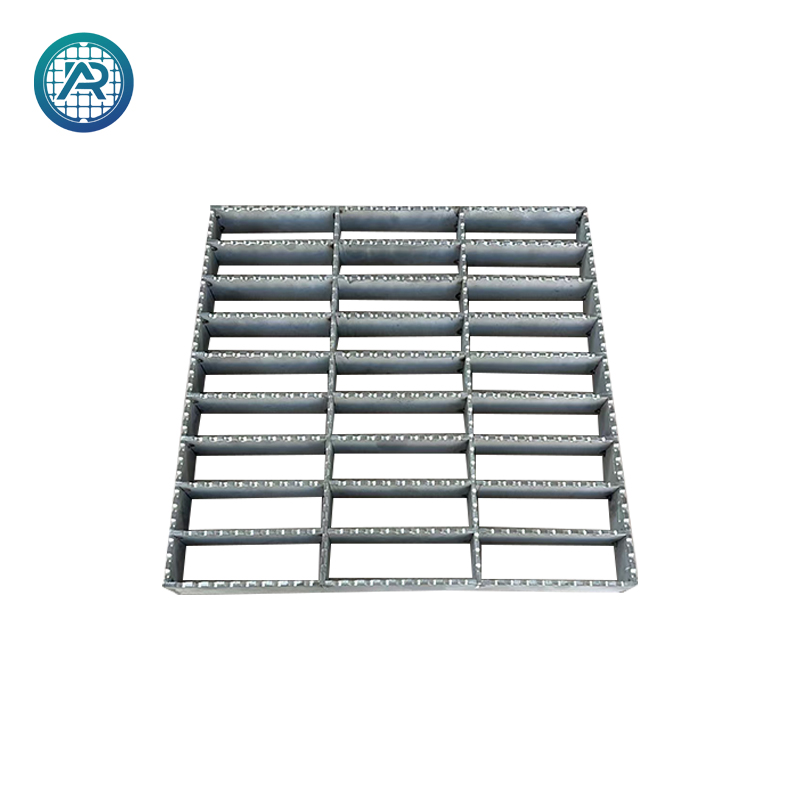

Hybrid FRP-Steel Grids: For ultra-high-load zones (e.g., port container yards), steel-reinforced FRP composites achieve 80-ton capacity while retaining 50% weight reduction.

2.4 Anti-Theft and Eco-Friendly

The non-metallic nature of FRP manhole covers

eliminates scrap value, deterring theft. In Johannesburg, South Africa,

theft rates dropped by 92% after replacing 1,200 cast iron covers with

FRP.

Sustainability Metrics:

Carbon Footprint: Producing 1 ton of FRP emits 1.2 tons of CO2 vs. 2.8 tons for cast iron (source: ISO 14040 LCA).

Recyclability: Post-use FRP man hole cover can be ground into filler for asphalt or 3D-printed construction materials, achieving 85% circularity.

3. Application Scenarios

3.1 Smart City Infrastructure

The integration of IoT sensors transforms frp man hole cover into data hubs:

Flood Prevention: In Tokyo’s “Super Levee” system, pressure sensors in FRP covers trigger real-time alerts when groundwater levels exceed thresholds.

Gas Leak Detection: Barcelona’s utility grids use methane sensors embedded in covers to pinpoint leaks within 0.5-meter accuracy.

Future Vision:

Self-Powered Sensors: Piezoelectric modules harvest energy from foot traffic to power IoT devices, eliminating battery replacements.

AI Predictive Maintenance: Machine learning algorithms analyze vibration data to predict cover wear, reducing repair costs by 30%.

3.2 Renewable Energy Facilities

FRP manhole covers dielectric properties make it indispensable for renewable energy projects:

Offshore Wind Farms: FRP covers in Denmark’s Hornsea Project 3 withstand 15% salt concentration and 120 km/h winds.

Solar Farms: Lightweight FRP man hole cover reduces soil compaction around cable trenches, preserving panel efficiency.

Case Study: California’s Solar Highway Initiative

Requirement: Non-conductive covers for 200 kV underground cables.

Solution: Custom FRP man hole covers with fire-retardant additives (UL94 V-0 rating) and EMI shielding.

Outcome: Zero electrical interference incidents over 5 years.

3.3 Urban Renewal and Heritage Conservation

In historic cities like Rome, FRP manhole covers blend functionality with aesthetics:

Custom Designs: Laser-etched replicas of ancient Roman patterns meet load requirements while preserving cultural identity.

Vibration Damping: FRP manhole cover low acoustic resonance protects underground relics from construction vibrations.

Innovation in Action:

Transparent FRP: For tourist areas like Paris’ Catacombs, translucent covers with LED lighting showcase underground history.

4. Future Trends: Smart and Global Expansion

4.1 IoT-Driven Smart Covers

The next generation of FRP manhole covers will feature:

5G Connectivity: Enabling real-time data transmission to municipal dashboards.

Edge Computing: On-board processors analyze data locally, reducing latency.

Market Forecast:

The global smart manhole cover market is projected to grow at 18.7% CAGR, reaching $1.8 billion by 2030 (Grand View Research).

4.2 Global Market Penetration

Emerging opportunities include:

ASEAN Infrastructure Boom: Thailand’s Eastern Economic Corridor plans to install 500,000+ FRP manhole cover by 2030.

EU Green Deal Compliance: FRP man hole cover eco-profile aligns with mandates to phase out cast iron in public projects by 2035.

4.3 Material Science Breakthroughs

Graphene-Enhanced FRP manhole cover: Adding 0.1% graphene increases tensile strength by 40% (University of Manchester trials).

Self-Healing Resins: Microcapsules release healing agents when cracks form, extending lifespan to 50+ years.

5. Conclusion

From coastal megacities to smart grids, FRP manhole cover is redefining resilience and sustainability. As material science and IoT converge, the humble frp man hole cover evolves into a linchpin of tomorrow’s infrastructure—proving that innovation lies not just above ground, but beneath our feet.