Steel grating is a fundamental component in modern construction and infrastructure, serving industries, municipal projects, and architectural developments with a reliable solution for flooring, drainage, and safety. As industries evolve, the demand for high-quality industrial grating, custom grating, and galvanized grating continues to increase, with applications spanning factories, warehouses, ports, airports, and city streets.

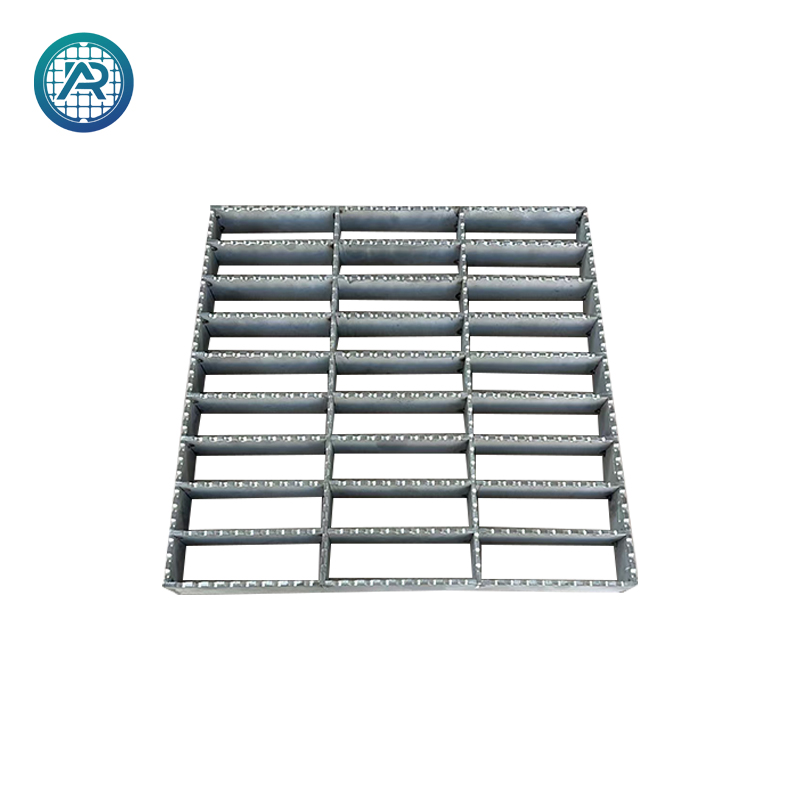

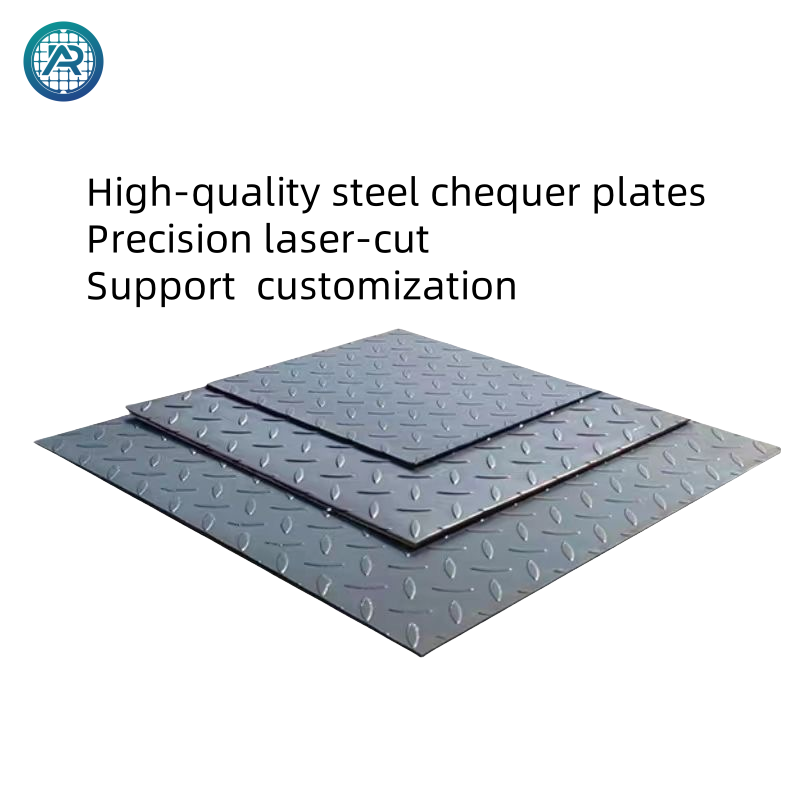

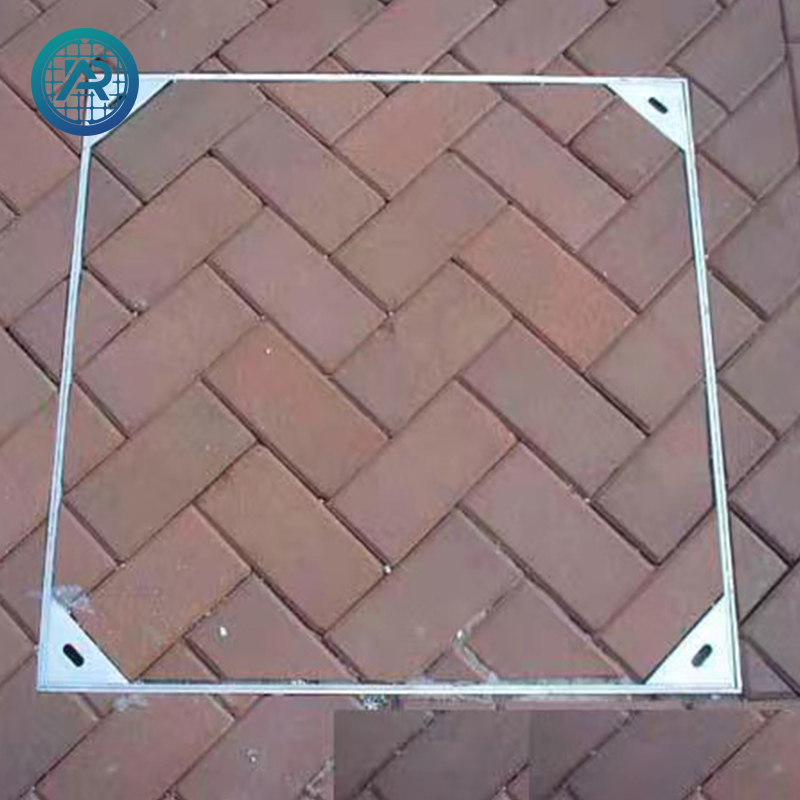

The production process of steel grating begins with the selection of high-strength steel, which is cut and welded precisely to create a durable grid structure capable of handling heavy loads while allowing water and debris to pass through. This feature makes steel grating an essential choice for drainage systems in urban environments and industrial sites. Custom grating offers tailored solutions to match specific project requirements, ensuring the right size, mesh configuration, and thickness for various applications, including catwalks, platforms, stair treads, and trench covers.

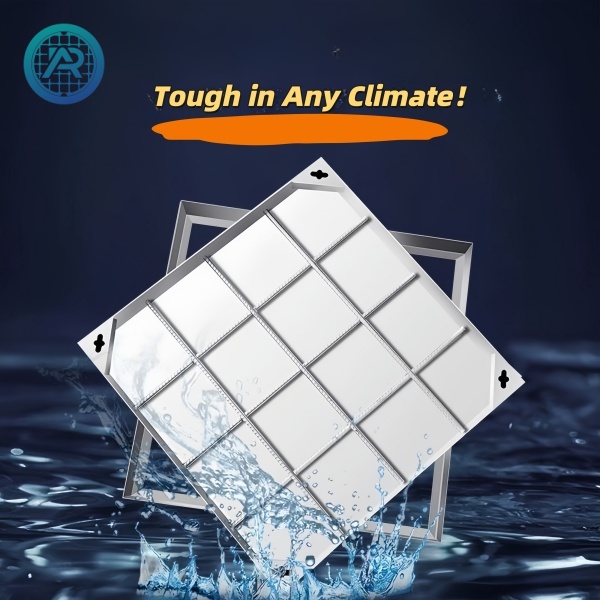

Galvanized grating plays a critical role in enhancing the lifespan of steel grating by providing resistance to corrosion, moisture, and harsh weather conditions. This zinc-coated layer helps in maintaining the structural integrity of the grating, making it suitable for outdoor and high-moisture environments such as wastewater treatment plants, chemical plants, and marine facilities. The galvanizing process involves immersing the steel grating in molten zinc, ensuring complete coverage and long-term durability.

Industrial grating is used across a variety of sectors to support heavy machinery, vehicles, and pedestrian traffic. Heavy-duty grating, a subcategory of industrial grating, is designed to handle high-load conditions while maintaining safety and stability. It is commonly installed in areas with significant foot and vehicle traffic, such as factory floors, loading docks, and logistic centers, providing a robust and long-lasting flooring solution.

Additionally, steel grating is utilized in architectural applications for its aesthetic appeal and functionality. The open-grid design allows light, air, and water to pass through, making it suitable for facades, sunscreens, and ventilation covers. Architects often choose custom grating designs to integrate into modern structures, providing an industrial yet clean look while maintaining practicality.

The manufacturing of steel grating involves strict quality control measures to ensure compliance with international standards and project requirements. Each piece undergoes rigorous inspection, including load testing and surface treatment checks, to guarantee performance and reliability. Packaging and logistics also play a role in ensuring the grating reaches project sites without damage, ready for immediate installation.

Regular maintenance is essential for extending the life of steel grating in service. Periodic cleaning to remove debris and checking for signs of corrosion can prevent blockages in drainage grating systems and maintain the safety of walkways and platforms. For galvanized grating, occasional inspection of the zinc coating helps in identifying any areas that may require touch-ups to prevent rust.

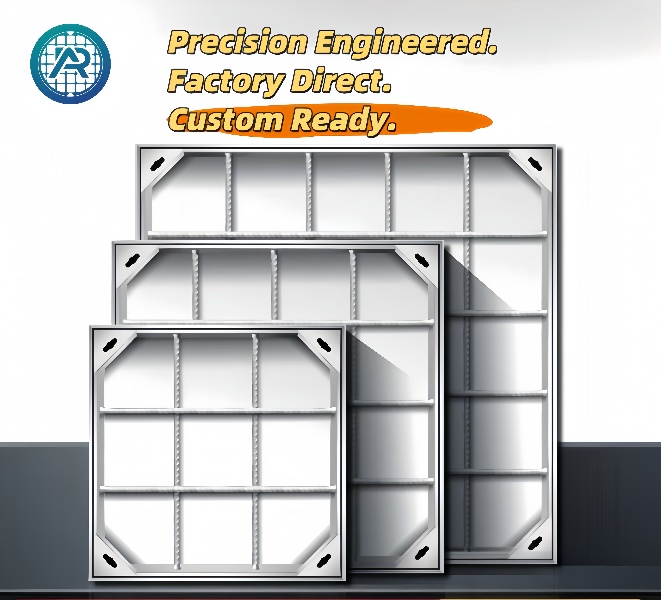

Our factory specializes in the production of steel grating, custom grating, galvanized grating, and industrial grating, providing complete solutions for diverse projects worldwide. We utilize advanced production technologies, precise fabrication methods, and strict quality assurance protocols to deliver high-quality grating that meets the unique needs of our clients. By focusing on durability, safety, and cost-efficiency, we help clients achieve long-term value in their infrastructure and construction projects.

Choosing the right type of grating is essential for project managers, engineers, and contractors who seek reliability and efficiency. Whether it is for industrial flooring, drainage systems, or architectural design, steel grating offers a versatile and effective solution, ensuring safety and functionality across various applications while contributing to the development of sustainable and resilient infrastructure globally.